Student Hostel Project at City University of Hong Kong

Company: CIMC MBS Hong Kong Limited

Location: Hong Kong, China

Gross Size of Project: 516,667 Square Feet

Days to Complete: 721

Award Criteria

Architectural Excellence

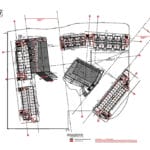

This project is currently the world’s largest student hostel (calculated by the number of bed spaces) to have adopted volumetric modular construction technology. It was completed by the end of 2023, and operational by early 2024, two years ahead of the original schedule.

It consists of 6 buildings ranging from 13 to 18 stories, with a total of 1,344 modules, with more than 2,000 bed places, significantly reducing the accommodation shortage that CityU is currently experiencing. In addition to hostel rooms, there are communal rooms, corridors, rest rooms and plant rooms constructed using the CIMC MBS. The hostel complex offers high-quality accommodation and learning space, large amounts of open green spaces, plus academic and amenity facilities where students from all over the world can explore their aspirations and potential together. There are also numerous public spaces such as the semi-outdoor green decks at each hostel building where students can mingle and hold activities.

Technical Innovation & Sustainability

Multi-trade Integrated Mechanical, Electrical and plumbing (MiMEP) technology was also adopted for this project. The pre-assembled MEP cassettes were integrated and installed in the CIMC factory within the MiC modules. Up to 90% of the aluminum cladding system was also prefabricated and installed in the factory, including the projecting horizontal and vertical fins. The aluminum feature fins were designed to conceal all the external pipe works providing an attractive appearance whilst also providing access for future maintenance. The project has also adopted several green elements that promote sustainable living and explore smart living technologies. For instance, 200 photovoltaic panels on the roof of the residential tower blocks will save energy and electricity costs. The on-site installation method can reduce construction waste and dust by 68%, minimize the impact on the neighborhood by 75%, leading to improved environmental performance.

Cost Effectiveness

The use of modular construction methods, which involves the fabrication of modules in a controlled factory environment with 95% integrated rate (including all fitting out finishes, building service systems, furniture, doors and windows, and aluminum cladding etc.), offers numerous advantages, including better quality control, higher productivity, and improved cost-effectiveness.

The project has a cost-effective building management system will generate real-time data for security control and overall building maintenance, among others. This system caused a construction time reduction, onsite labor requirement and cost reduction, construction noise reduction by 75%, construction waste reduction by 68%, fully code compliant and excellent quality control by volumetric modular construction technology, excellent fire performance, excellent acoustic performance, MEP services fully installed, tested, and commissioned.

See More Awards of Distinction Winners

To view all our current honorees, visit our main Awards page.