Mapleton Crescent

Company: MJH Structural Engineers

Affiliates: Vision Modular Systems, Tide Construction

Location: London, England

Gross Size of Project: 80,000 Square Feet

Days to Complete: 120

Award Criteria

Architectural Excellence

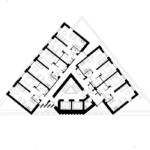

Mapleton Crescent is an iconic 27-storey tower in south London delivered for Pocket Living in just 18 months. It contains a mix of apartment types, 60% of which are affordable. The scheme was originally designed traditionally, but volumetric delivery was key to making the highly constrained 450m² site, bounded by a transportation Red route, a shopping centre and the River Wandle, viable. The tower covers the site’s whole triangular footprint. This was made possible by the innovative construction method, which involved assembling the building from above. The slimline three-sided core provided the base for a single crane to position all 283 fully fitted, loadbearing units in eight weeks, at a rate of eight units a day. Volumetric manufacture accounted for three-quarters of construction, but less than 8% of total construction time.

Technical Innovation & Sustainability

Mapleton Crescent is manufactured with the Vision wall supported system which is at its most cost effective in to the mid 20 storey heights. Above this height VMS switch to the corner supported system. The system has received accreditation from various authorities and the engineering design has been verified by experts in the field. The system used in these modules has previously been used to construct the 25-storey modular building in Wolverhampton although the system is more efficient due to an almost continual process of refinement through R&D. Once the engineering and buildability issues were understood and developed to a practical level the teams at MJH & VMS set about refining the system at every level through fabrication, manufacture, assembly and erection. Each element of the construction is inspected and reviewed to understand the requirements and determine where advancement can be achieved.

Cost Effectiveness

The use of steel framed modules combines the high strength to weight ratio of the structural material in an efficient manner to maximise the benefits of offsite manufacture. At a very early stage of a project the range of steel sizes required are easily identified and stock levels managed to ensure smooth running throughout the project. The use of steelwork allows various elements of the modules to be manufactured early and efficiently stored due to the flatpack nature of these assemblies. This ensures lean and efficient manufacture with very low risk of delays. The manufacture of the modules runs in parallel with the onsite construction and a calculated amount of storage of the finished modules ensures continuity of construction and placing of modules on the critical path as the fastest route to completion. The majority of a residential building such as Mapleton Crescent is finished in the factory so on-site work is minimised and speed of completion is maximised.

See More Awards of Distinction Winners

To view all our current honorees, visit our main Awards page.