Developing the Next Generation of Modular Industry Workers w/ Modern Building Systems [podcast transcript]

Developing the Next Generation of Modular Industry Workers w/ Modern Building Systems

In this episode of Inside Modular, Alan Rasmussen, VP of Production at Modern Building Systems, talks about the industry's current workforce challenges, what he's doing at Modern to recruit and train the next generation of modular industry workers, and how companies around the country can take advantage of student technical education programs.

John McMullen

Hello and welcome to Inside Modular: The Podcast of Commercial Modular Construction, brought to you by the Modular Building Institute.

Sponsored ad

With a compact footprint, variety of unit options and seamless system management, City Multi-Variable Refrigerant Flow Zoning Systems from Mitsubishi Electric Train HVAC US are a one-stop solution for modular projects. With efficient operation and the ability to connect to commercial ventilation equipment, third-party systems, and comprehensive control solutions, City Multi-VRF can help you meet energy and performance goals on your next project.

From off-site development to on-site assembly, you can trust our manufacturer-level support to guide you from system selection to design to startup no matter the application.

To learn more about our offerings visit Mitsubishipro.com

John McMullen

Welcome, everyone. My name is John McMullen and I'm the marketing director here at MBI. Today I'm talking with Alan Rasmussen, Vice President of Production at Oregon-based Modern Building Systems. Alan will be talking about workforce challenges in the industry, and what it takes to find and develop new modular industry workers.

John McMullen

Alan, welcome.

Alan Rasmussen

Hey, thank you, John. It's a pleasure to be here.

John McMullen

Always good to talk to you. So, we've known each other for a while now, but for those who haven't met you, or have only met you briefly, I know your family, rather, has been in the industry for a long time. Can you tell me a little bit about that?

Alan Rasmussen

Yeah, so Modern, we just celebrated our 50th anniversary last week. So, we're proud of that to be in this industry for 50 years. There's been a lot of people that come in and out of the industry, but we take a lot of pride in being a solid rock in this industry. My grandfather started the company, and he was in fact one of two 2022 modular Hall of Fame recipients. So, we're very proud of him and his legacy and we look forward to carrying that on.

I represent the third generation of Modern Building Systems along with my cousin who served as our CFO. Our goals and visions are for a fourth generation. So that's what drives us here every day. We're located out headquartered out in a small town called Aumsville, Oregon. The only two commercial modular manufacturers in the state of Oregon are both located in a small town. Blazers just right across town, and we see each other at the US sporting events, the grocery store and the restaurants. It's a fun little dynamic for sure.

John McMullen

Oh, it's very cool. That’s very cool. So, you've been in and around the building industry for a long time now. I was wondering if you could speak to any of the trends that you've seen in the past several years. How has the industry changed?

Alan Rasmussen

Well, a lot out here is the energy code here on the west coast, the energy code is very progressive, and constantly changing. It kind of feels like the state of Washington, Oregon, and California all try to outdo themselves on the code. So, we've been scrambling quite a bit and reacting to that for the new energy codes. So, it's kind of unique when I serve on the Board of MBI and when I get to meet with our colleagues at board meetings and whatnot. Some of the things I tell them about what we do here in the energy code codes, they're kind of blown away by. So that's been a big one, the Green Building Movement has pushed the energy code quite a bit. It's been really directed at stick build buildings, but that slowed down to your mobile office trailer.

It's kind of crazy, some of the things that we have to do to a mobile office trailer out here, such as control receptacles, censored lighting, motion sensor, lighting, and the bard units. I think Bard has to build a special unit just to get through the energy code out here. So, that's been a big one. For the topic at hand today, I mean, workforce has been tough. The recession really took a lot of people out of the construction industry, trying to get over the stigma of a job in the construction industry. Then, this last recent history of COVID, it took a lot of people out of the workforce. Stay at home to be safe or stay home to take care of their kids who were not in school anymore. We're just now seeing that kind of pre up again, more applications coming in and that's been good. We cross our fingers as this next variant comes through that it doesn't slide back. So, those are some of the some of the trends I've seen.

John McMullen

How has Modern itself been affected by the workforce challenges?

Alan Rasmussen

Well out here like I mentioned, Blazers is right across town, so you have two modular factories in a small town competing for labor. We also have lumber mills and plywood mills within 15 miles that are very labor intensive, competing. So that's been tough. There are some jokes between HR folks that we look at resumes, and it's like, oh, they've been here, here, and here, they just kind of circle around in our small Canyon area that we are located in, it's really hurt. I mean, there's times you want to crank up that factory and kind of get going and you can't do it. You need some hands on the line, and you just can't get them there. So, it's hurt a little bit to go at the speed that we'd like to go and serve our clients.

John McMullen

So, you alluded to this earlier with all the other employers in your area, but have you seen this as an issue for the modular construction industry only or is this a sort of broader industry issue?

Alan Rasmussen

No, it's definitely a broader industry. A lot of my friends are residential home builders, and they may necessarily not need a bunch of labor themselves, but their subs are drastically affected. Just getting, scheduling subs, the same kind of stick to a project is just the same as trying to crank up the factory speed. You just can't do it, because there's just not enough bodies and work hours in the day. I've seen a lot of what the National Home Builders Association, they're really pushing a campaign to bring more people into the trades. I really feel like that's a space that the Modular Building Institute could do. Our industry could do some things because I think we've got some really great advantages that we could compete against the stick-built world to bring really skilled labor into our industry.

John McMullen

Have you noticed one region in the country dealing with these shortages or is this more of a nationwide challenge?

Alan Rasmussen

Well, I'd say from my perspective, I think it's a nationwide issue. Like I mentioned, when I sit down at the board meetings, and we kind of share our war stories together. After the meeting, it's one of the questions I ask like, hey, how's labor going? If it's down in Texas, or the southeast or the northeast, Midwest, I get the same answers. It's just tough right now and we just need to get the labor participation rate way up in this country. Again, like I said, I think the modular industry has a great advantage to bring people into skilled trades.

Related Reading:

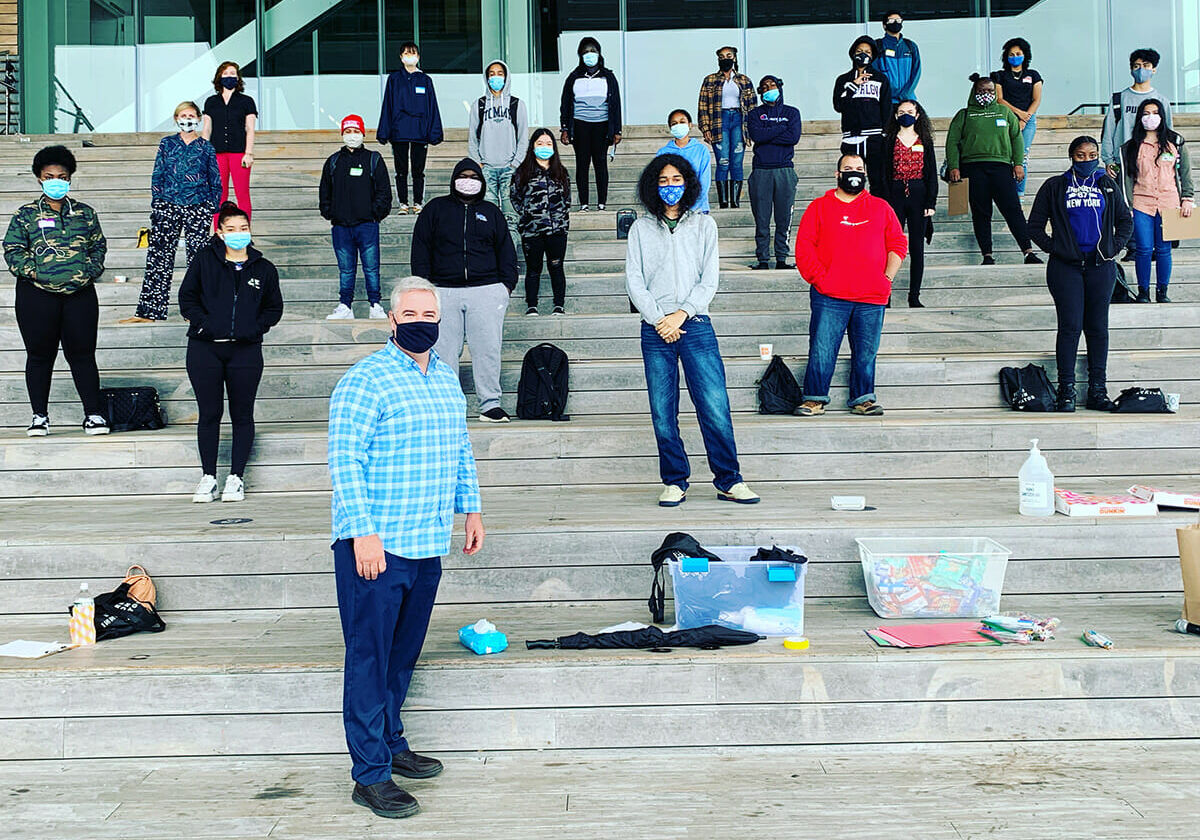

Triumph Modular Collaborates with Year 13 to Teach the Next Generation of Construction Leaders & Innovators

Year 13 is for students to discover what they’re passionate about before committing to pursuing a career in a given field. There’s no cost to students for the program. Founder Dr. Sarah Cherry Rice says, “Year 13 serves as a bridge to connect students — particularly low-income students and students of color — to pathways of economic mobility and success in Boston’s innovation economy.”

John McMullen

What challenges is the industry facing to bring in and train workers? I guess not just modular, but the building industry in general. What challenges are they specifically facing?

Alan Rasmussen

Well, again, I think there's a stigma against the construction industry that it's lesser than or dirty, really demanding, and there's cooler jobs to be had out there. I think our industry specifically, people think, Oh, it's just the manufactured home plan. That's boring. It's repetitive. Not a lot of excitement there. That's not the case. I think especially these commercial modular manufacturers, we're building some great products. These projects are very interesting. There's a lot of opportunity there.

John McMullen

So, what's Modern done to bring in workers and really develop talent over the past few years?

Alan Rasmussen

Yeah, this is this has been a real passion project of mine. To be kind of honest, it started out as very selfish. I'm just going to flip over any stone I can to find labors, construction workers. Our local area Salem, Oregon, the State Capitol, which is about 10 miles away, it's comprised of about eight high schools, and a very generous donor, who's a developer in town, set up a career technical school and it's a great model. These kids, they get bussed across town into the school and instead of just one hour of shop class, these students spend two and a half days at this school. So, their English classes tie to their construction program. So, they could be doing submittals, it could be reading plans, it could be writing bids. Their math class is tied to what they're doing. It could be geometry of figuring out the yards needed to pour foundation or angles for the rafters on the roof. So, I kind of got invited to check it out, and have been involved for at least four or five years doing mentoring programs, doing job fairs there, hosting tours at our factory and frankly, recruiting these students. There's also a nonprofit subsidiary that builds a house every year. So, the students get bussed out and they spend about four hours every other day out at the house project, framing, roofing, siding, doing finish carpentry doing all the phases.

So, I've been involved in that board, too and we recruit those kids. There's a great dovetail from their classroom because they're in a big warehouse space as their classroom. That greatly resembles the modular factory. So, when they transfer when I do recruit them in, and they transfer they come to work for Modern. It feels like home to them, they've been in this class their junior and senior year and Modern looks and feels a lot like their classroom back at the career technical school. When the pandemic hit, my wife's a high school principal, and I kind of knew what was going on. Kids were just scrambling, schools were scrambling like crazy, just to put some curriculum together. Kids were kind of sitting at home twiddling their thumbs, and there were some that I had just done a mock, you know, they'll do these mock interviews, to help build these their professional skills and I would tell them, I'll come in and do it, but I'm going to interview for real, I'm going to offer them jobs, and they're totally fine with that. They love that.

I had talked to him maybe a few weeks before the pandemic first hit. Then it kind of dawned on me one day I go, man, some of these kids that I was planning to talk to, and have them come on board when they graduated, or when the summer hit, are probably just sitting at home. I called a couple of them. I'm like, hey, do you want to come to work and they're like, sure. They still had some online school responsibilities and we worked it out that some days, they didn't have any, and they could put in, you know, eight hours a day. Some days, they needed to be on their computer for a couple hours and do an online class. We just had them clock out and I basically set up my conference room as a classroom for them. They would clock out and then come in and sit down in the conference room and do their school, eat their lunch, then clock back out and clock back in.

We've kind of done that model going forward. A lot of them when they hit their senior year, they don't have a full five-day school week, so I have several students right now that go to school two days a week and they work for me three days a week. Some of them go to school three days a week and work for me two days a week. When the summer hits, they're full time. So, it's been great.

Early on, I would say my station leads, my framing supervisor, finish supervisor, they were very leery of it. All these high school kids and now they'll tell you they've done such a great job at this career technical school teaching them that they prefer them. They want them on their crews, they want them in their stations. I will tell people reach out to those programs. Across the nation, they're talking about career technical schools and construction is always one that's usually prevalent in those programs and to connect with them.

John McMullen

So, you mentioned earlier the stigma that some people have against construction in general and doing that hands on kind of work. What's the feedback been from these kids who have come to work for you, who are in the factory doing real work? What sort of feedback have you gotten from them?

Alan Rasmussen

Well, they're so eager. A lot of these kids have never had a job before and if they have, it's been pretty light, maybe bagging groceries or something. So, they're really eager. They chose to go into this career technical school program. So, they're very eager to put those skills to use and make money on it. A lot of their friends that maybe some of their friends who do have jobs, minimum wage, and they're getting $5, 7, 8, 9 more an hour than their friends.

So, they're very eager to come in, work and it's kind of funny, they'll tell me they like coming and working in the factory over going to the House Project, the stick-built project site that they have for part of their senior year project. I'm looking out the window right now and it's 38 degrees and raining. They much prefer to come into the factories. It's nice and dry and they prefer that work environment. I've kind of alluded to it a few times earlier in this conversation is I think that's where we need to as an industry, highlight those advantages to come in and work in those controlled environments in the construction period.

John McMullen

So, you have alluded to those several times and I was going to ask what are those advantages that modular has over the stick-built construction, traditional construction industry? What can modular offer workers that they can't?

Alan Rasmussen

Well, first off is just the working conditions. The winter might be cold, snowing, raining, depending on where you are in the country. The other thing is schedule predictability. I've had plumbers and electricians who I've been able to recruit in because they're out in their work van and driving here and there, they don't know where necessarily, where they'll be one day or the other. In some of these big urban markets, they get stuck in traffic for an hour after work trying to get back to the shop and get in their truck and go home.

So, the schedule predictability, being able to tell their family when they're going to be home, being able to volunteer their time to coach their son or daughter's sports team. They like that. They like having that predictability. I have a electrical apprentice who's newly married, she's looking to start a family soon. She worked a couple of years in the traditional stick-built world as an electrical apprentice and she didn't see a path to be able to be a mother and do that career at the same time, just because of those factors that I talked about. She loves it here at Modern, she loves having a set, schedule predictability, and still be able to work in this and a very well paid a skilled trade labor job, and we're happy to support her in that. So that's awesome.

I think those are just some of the things that we need to as an industry and these companies in these industries, keep that in mind when you recruit these people. There are some great advantages.

John McMullen

So, based on what you're doing in the community, Modern, and what you've seen elsewhere, what ideas do you have that might help other manufacturers and builders bring in new workers?

Alan Rasmussen

Well, touching back on that career technical school. I would do these job fairs, or do these mock interviews, and with the work safety rules in this country you really can't have anyone under the age of 18 in your factory, swinging the hammer, using the nail gun or using the saws. It's like these students were eager to work, but I'd have to ask, hey, when are you going to turn 18? I could hire a few to clean and sweep up, but that's not going to set them on fire for the trades.

So, I started talking to a few of our contacts in the local Oregon legislature. They said, well, we can do an Oregon law, but it'll be superseded by federal law. I got talking to the Bureau of Labor and Industries here in the state of Oregon that has a child labor division, and it goes, hey, what you need to look at is this in the federal work safety law, there's something called a Student Learner program. We looked into that, and it's this collaborative between a school and the student is in some sort of CTE program. Maybe it's not as robust as what Salem Kaiser Public Schools is doing here in Oregon, but maybe it's just their one period shop class or whatever.

You have a document signed by the school, the guardian, parent, the student, the company, and they're an employee of mine, the work comp coverage is mine. By doing that, you can bring in students that are under the age of 18 and those restrictions on being in that setting, and what they call a hazardous work environment, you can be in that setting. You can use the tools.

So, I've been able to bring in labor that before wouldn't even cross your mind. They've been able to work in a collaborative with what they're doing in school and still meet the federal work safety laws. So that law, that path is out there. I encourage other modular companies to look at that and work with the local schools and those students.

John McMullen

Very cool. I learned something myself, so I'm glad we had this conversation. To the workers themselves, what's your pitch for working in modular construction?

Alan Rasmussen

Well, when I talk to people, talking to a perspective client, or even a client, what is this building we're building? One fun little phrase I use is, this is adult Lego building and we work fast. Their speed, it's changing every day. There are new and exciting projects, not every project is the same. So, one project to the other, we build those buildings a different way, it's a different set of Legos. As a child, you get bored playing with the same Lego set over and over. We get a great variety every day. Again, some of the advantages I've already mentioned, to just the schedule predictability, that work family life balance that can be achieved, and still work in construction. Much safer. In our factory, in most factories, roofing is by far more safer job tasks than it is out on a site-built construction project. We want you to come in and work and definitely go home to see your family. This industry is just safer. It's not as demanding and working in the environments. And it's fun.

John McMullen

So, it's almost at the at the end of this interview, before you go: Tell me what's going on at Modern. What's on the horizon for 2022?

Alan Rasmussen

Well, we got some exciting stuff. I'm sitting here in our conference room chatting with you and I'm looking at a big set of plans in front of me, but a lot of swing space for schools. One I'm looking at the table here, it's going to be the school, it's a rural school district that needs to expand. They don't necessarily want a village of double wide classrooms. They can't quite afford stick-built construction, that's booming in costs. So, their five-classroom addition is going to be built with modular. So, we're going to tie it right into the existing school building. It's going to match the existing architecture. Those are the projects we get excited about. We're pretty heavy in the education industry and providing them solutions that don't necessarily have to be the double wide classrooms. They get pretty excited about that and have a few others like that per school district. So, I’m looking forward to it.

John McMullen

There's a great need for those education projects. My sons right now are in double-wide classrooms. Their school has gotten too big and they're doing that for the time-being until a new school can be built.

Alan Rasmussen

Yeah, that's the conversation we have with our school districts. There's something in between there, take a look at that and think long term solutions utilizing modular construction.

John McMullen

So, one last thing, I was hoping you could help me hype up MBI’s upcoming World of Modular in April. We're going to be back in person in San Antonio on April 25 through the 28th. I know you've been an attendee for a long time. Why do you and Modern keep coming back to World of Modular?

Alan Rasmussen

Well, I mean, this year, especially back in person, that should sell in itself. It's going to be big, it'd be nice to see everybody again. San Antonio, Texas in April will be nice and warm. Those from the northeast, up here in the northwest, and especially our Canadian members come and thaw out per se but it's always just a good time to catch up. We're a small niche industry, we're growing, but there's a great fraternity and it's always good to see the other people in your industry and learn from them, just chat with them, support each other. So, it's definitely worth the trip down and we really look forward to seeing everybody down there. As a board member, this is a this is a big piece of MBI’s budget every year. So help come support us so we can keep doing great things for you guys.

John McMullen

Well, thank you, Alan, I really appreciate you being here today. I learned some things and I'm looking forward to seeing you in April in San Antonio.

Alan Rasmussen

Alrighty, John, looking forward to it.

John McMullen

My name is John McMullen, and this has been another episode of Inside Modular: The Podcast of Commercial Modular Construction. Until next time.