Pacific Drive Elementary School

Company: Silver Creek Industries

Location: Fulleton, California, United States

Gross Size of Project: 255 Square Feet

Days to Complete: 21

Award Criteria

Architectural Excellence

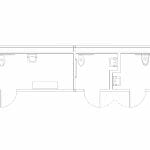

To meet the needs of the growing student population the Pacific Drive Elementary School need a fast and cost effective solution to provide additional restroom facilities. This new modular restroom facility includes three gender neutral single occupant restrooms. One of restrooms has been designed to accommodate a changing facility for special needs students. The building exterior utilizes fiber cement wall panels to provide a durable finish system. A large overhang with a standing seam roof system provides shade and weather protection at the restroom entrances. Durable and easily cleanable finishes were used throughout to minimize maintenance concerns.

Technical Innovation & Sustainability

To meet the project requirements in the most efficient and cost-effective manner a custom 8.5’x30’ module design was utilized. A single module is used to construct the entire building, this allowed all fixtures, systems and finishes to be installed in the factory. Due to the possibility of future relocation the building the finish selections are durable to avoid cracking during transportation. High efficiency LED lights with occupancy sensing controls were used throughout the project. Low-VOC materials were used throughout the project to provide a healthy learning environment. High recycled content materials were utilized wherever possible. Low-flow plumbing fixtures were used throughout the project.

Cost Effectiveness

The project owner recognized early in their planning process that a modular construction solution was the most cost-effective project delivery method for their new restroom building. By utilizing off-site construction methods they were able to realize significant schedule advantages as compared to traditional construction. The accelerated nature of a modular construction process allowed for a reduced development impact on the project site. Since a single module was used to construct the building all interior and exterior finish work was performed in factory which allowed for a quick and easily building installation on site.

Green Building

The Firefighters module is made with a steel frame and infill panels in rock wool sandwich panels having a thickness of 100 mm with steel plate support.

A fire resistance of 120 minutes (E.I. 120 - Reaction to fire in accordance to UNI EN 13501-1: A2-S1-d0).

The use of rock wool in green building construction is completely safe and in accordance with current regulations, environmentally friendly as it is a natural fiber given its rocky origin.

The 'U' transmittance of the wall and ceiling is equal to 0.40 W/m2 K (in accordance with UNI EN 14509 A.10) ensuring maximum thermal and acoustic comfort.

The premises are ventilated and illuminated by daylight, making the most of natural resources.

See More Awards of Distinction Winners

To view all our current honorees, visit our main Awards page.