CVN 78, USS Gerald R. Ford Modular Building Installation

Main Category: Modular Building Design

Company: Mobilease Modular Space, Inc.

Location: Newport News, VA

Building Use: Office, Work Space, Conference Room

Gross Size of Project: 16000 Square Feet

Days to complete: 30

Award Criteria

Architectural Excellence

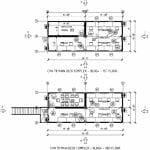

Newport News Shipbuilding, a Division of Huntington Ingalls, nation's largest builder of US Navy aircraft carriers, tasked Mobilease to install 7 temporary 2-story modular office buildings within a 30 day window on main and flight deck of USS Gerald R. Ford. The buildings supported Navy and Newport News Shipbuilding Carrier Programs while the USS Gerald R. Ford underwent its final maintenance phase to become operational. The space requirements were open concept except for a few director offices and conference rooms. Due to Navy safety and space requirements, non-combustibility, along with the need to overcome height restrictions on main deck, 7 2-story buildings were comprised of IteraSpace's OptiMax modules. With an 8'x20' layout and steel moment frame, OptiMax modules enabled total flexibility of space design within the given site constraints. The efficiency in which the OptiMax modules are installed and uninstalled, played into the strategic planning of the project

Technical Innovation & Sustainability

OptiMax modules are fully IBC compliant, non-combustible and able to withstand 165 mph wind speeds and CA earthquake loads when stacked 3 stories high. The 8'x20' footprint and weight of 5,600 lbs. per each, made the moves and placement straightforward. The innovative connections between the the modules made for simple conversions from standalone to complex buildings. The flexibility of the OptiMax design enabled windows and doors to be placed into individual panels and positioned anywhere needed within the buildings. Steel moment frame design assures longevity of OptiMax when moved from location to location and when assembled in different configurations. The frames are also coated with C5 to provide high durability against corrosivity when near saltwater. All materials used in the construction of the modular units are recyclable.

Cost Effectiveness

Because of the size of OptiMax modules and method of freighting (via flatbed), special permitting and escorts were eliminated and number of transportations to and from the staging area, were reduced. Although OptiMax modules are non-combust, our scope required fire suppression and fire alarm systems which were installed during the assembly phase and final connections made on main and flight deck. This allowed for time saved in the 30 day installation window. The efficiency of how OptiMax modules were assembled, also allowed for a rapid disassemble, given the 30 day time constraint was applicable during this phase of the project. Additional labor costs and sans the need for traditional set up material, provided further savings to the Client.In its future repurposing, OptiMax modules are easily reconfigurable, as there is no special cost to reuse them as single office or in any other configuration and thus further enhancing the cost effectiveness of its design.

See More Awards of Distinction Winners

To view all our current honorees, visit our main Awards page.