Khalsa School

Entry # 393540

Category: Permanent Education Under 10,000 sqft

Company: NRB Modular Solutions

Location: Calgary, AB Canada

Gross Size of Project: 7674 Square Feet

Days to Complete: 188

Architectural Excellence

Located in Rocky View County, the Khalsa School wanted to expand its facility to accommodate increasing student enrollment. A comprehensive master plan helped locate and organize the modular additions within the built environment. These modular additions were designed in a way that reflects Sikh culture. The proposed phases mirror the architectural massing of the school, creating a school courtyard, defined by the surrounding classrooms. This allows younger grades to enjoy exterior space while still being in a supervised area. The architecture introduces a shifting pattern, creating an element of playfulness across the façades of the modular addition. The shifting of the modules is accentuated with traditional Sikh colours: blue, the colour of the warrior, and orange, representing knowledge and wisdom. Simultaneously, two messages communicate the totality of the architecture. While the structure’s energetic façade connotes play, the colours speak to the Sikh way of life.

Technical Innovation & Sustainability

Prefabricated modular construction facilitated an expedited schedule during the summer holidays, which was one of the drivers for going modular. Using modular construction for the school was a decision based on reducing construction time and ensuring the quality of construction. With modular design, carbon emissions are kept at a minimum by reducing the need for equipment on site. Since all construction can be monitored, fewer mistakes are made, reducing time spent on construction, and further decreasing emissions. The cold climate means that the building must be adapted to cold weather. Hence, the project includes several thermal performance upgrades, from energy-certified windows and doors to extra insulation in all walls to boost R-values. Other features included high-efficiency HVAC systems for heating and warmth retention. The addition of these thermal upgrades has increased the R-value of the walls.

Cost Effectiveness

Modular construction provided a cost-effective solution for the Khalsa School. Most of the construction was completed in a controlled manufacturing facility, so project risk was reduced, along with the impacts of weather conditions and limited trade availability. By utilizing off-site construction methods, they were also able to realize significant advantages in scheduling compared to traditional construction. During the design process, the interior spaces were carefully planned to allow for integration with the existing school site. The project has a strong focus on energy efficiency, which provides long-term value and cost-effectiveness for the owner, including features such as LED fixtures and energy-certified windows and doors. Modular construction was the best choice to ensure cost certainty and a high-quality project for the children in the community to learn and thrive.

Clover Park School District – Thomas Middle School

Entry # 380991

Category: Permanent Education Under 10,000 sqft

Company: Pacific Mobile Structures

Location: Lakewood, WA United States

Gross Size of Project: 7544 Square Feet

Days to Complete: 214

Architectural Excellence

Clover Park School District needed an addition to their new middle school. Pacific Mobile Structures provided a 7,544-square-foot building. The building was placed by a crane and manlifts for safety and speed.

A site-installed parapet puts the building’s height at 16 ft two-inches, hiding the mechanical systems on the roof and offering a taller appearance. Brick siding placed by a mason onsite, metal accents, and identical windows complete the exterior of the building for an exact match to the existing middle school.

Storefront entry doors welcome patrons inside where they step under a nine-foot-six-inch interior ceiling. A wainscot of MDF lines the hallways, interrupted by aluminum storefront interior windows that peer into each classroom. Corkboard was placed in intuitive locations throughout the building, and custom-built cabinetry completes each classroom. The bathrooms feature ceramic tiles that climb up the walls bordered by more wainscoting.

Technical Innovation & Sustainability

The floor of this building is custom-built with thick wood and extra sheathing for overall stability, strength, and a reduction of underneath noise – a signature of the architect on this project. The spacing in the floor systems was 12 inches on the center rather than the typical 18, as well as an added 1 1/8th in floor decking, and a reduced spacing of floor joints.

Bilco Floor Hatches and a mechanically vented foundation allowed for the building to be set at grade for a clean look. There is a floor hatch and roof hatch inside the building for easy access to the foundation of the building and the mechanical units on the roof.

The entire building is insulated by sound-proofing mineral wall insulation for quiet classrooms. An Encelium control system with dual technology controls was installed so that aspects of the building such as heating, cooling, and lighting can be controlled from then main building and energy consumption can be tracked.

Cost Effectiveness

This building ultimately totaled to the same cost as a stick-built building, but a value-engineered mechanical system saved hundreds of thousands of dollars.

Mercer Island/Sage Complex

Entry # 381302

Category: Permanent Education Under 10,000 sqft

Company: Pacific Mobile Structures

Location: Mercer Island, WA United States

Gross Size of Project: 4624 Square Feet

Days to Complete: 235

Architectural Excellence

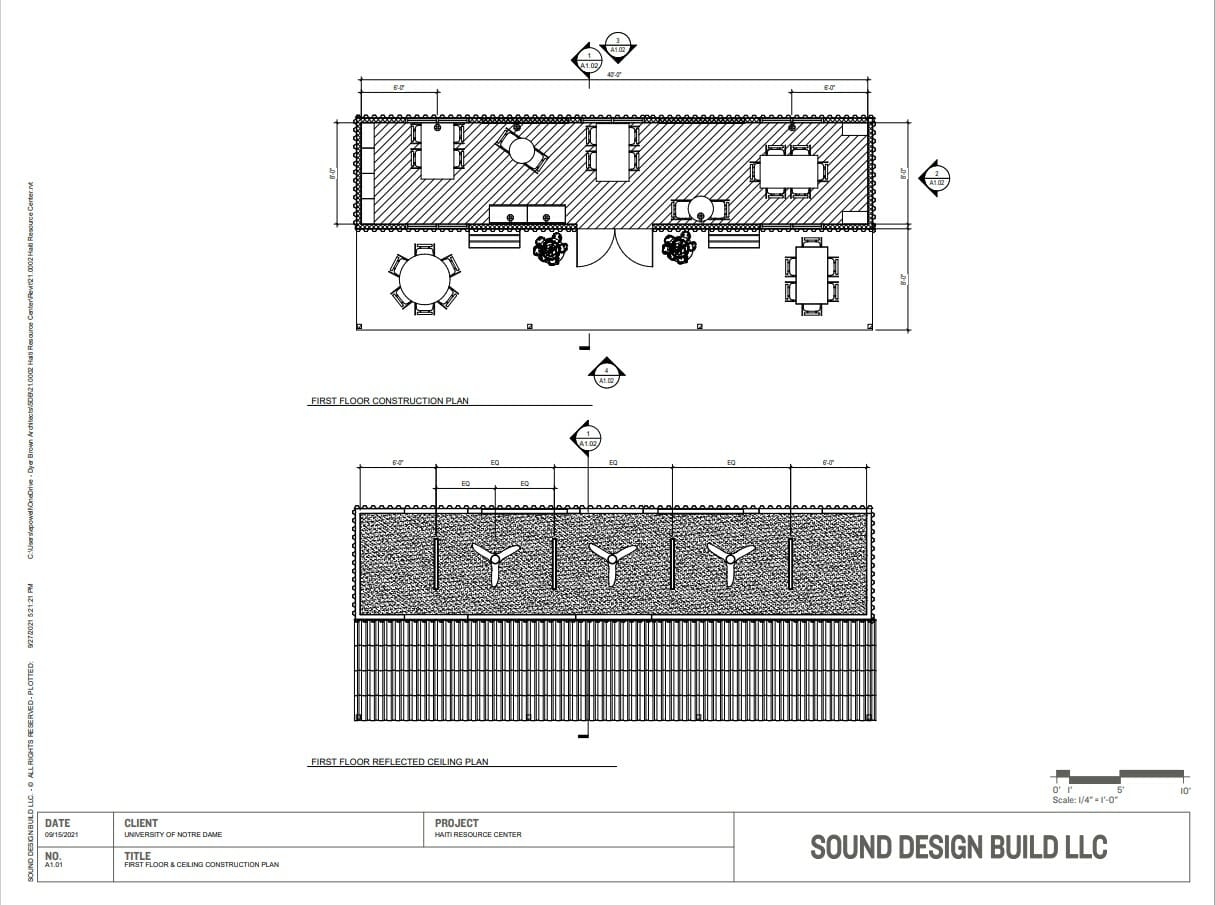

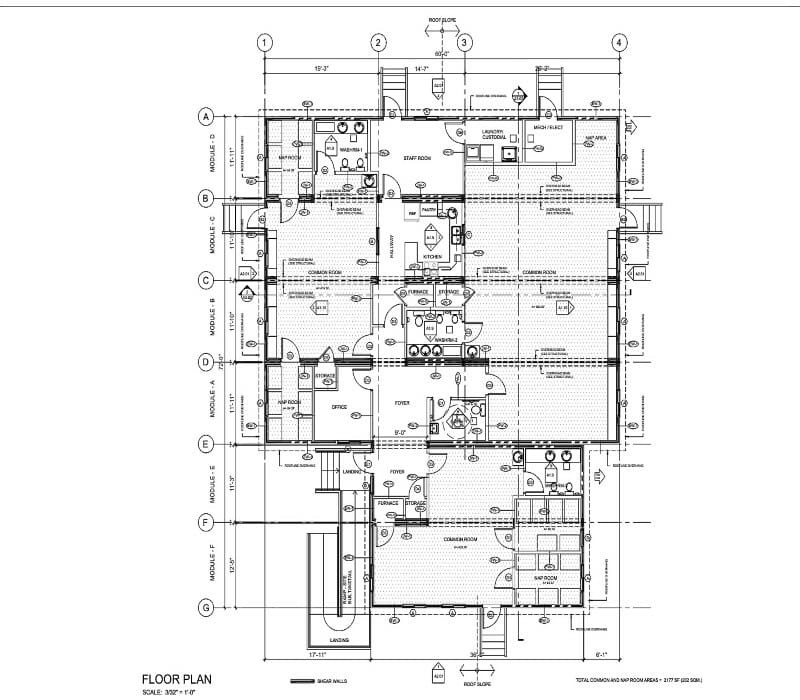

Mercer Island School District needed space for their life skills program. Pacific Mobile Structures provided a 4624-square-foot SAGE Complex. It is designed to look just like the main building, with a shed-style roof and an overall modern aesthetic. The interior of the building is divided into two sections: a classroom and a life skills center. The classroom features standard SAGE components including vaulted ceilings, fans, textured paint with cork accents, and pendant LED lighting. 32 feet of whiteboards with marker trays, 26 feet of cabinetry, cubbies, and coat hooks complete each classroom in addition to sinks and countertops. The life skills portion of the building features a 6-inch drop T-grid ceiling with fans, and bedrooms, a meeting room, a kitchen and dining area, a work room, and washer/dryer. The bathrooms feature a Hoyer Lift in the shower area with a ceiling track capable of carrying over 400 pounds to transport physically disabled persons between the shower and toilet.

Technical Innovation & Sustainability

Due to the layout of where this SAGE Complex was going to be placed, it had to be redesigned for every component to go in the opposite direction it normally would. Instead of being built in long sections, the building was built in shorter sections of 12 to 14 feet wide and 34 feet long. This resulted in an unusual number of modules. The bathroom modules were separated, the life skills portion of the building was built in five sections, and the marriage line and beams run the opposite direction. This is a totally new design approach and configuration of the SAGE Classroom and it’s the first time it’s ever been done. The building also had to be set on an all-weather wood poly wall above grade foundation to be careful not to interfere with the in-ground plumbing on the site. An ultra-durable aluminum ramp from Welcome Ramp Systems was placed all around the building, leading down into the parking lot for safe and easy access.

Cost Effectiveness

Even though the school district embarked on a more expensive build due to the constraints of the site, the SAGE Complex yields lower operating costs and cost effectiveness for the building user as a more energy-efficient building. Pacific Mobile Structures’ signature SAGE line was created to be a healthier, more efficient learning environment designed with cost effectiveness from the building user in mind. This particular SAGE building features a white TPO roof that refracts the sun, BIOPC in the walls that helps with tempering the highs and lows of the day-to-day climate, ERV with a mini split that is 40% more energy efficient than standard wall-hung units, and an abundance of natural daylight through clear story windows that’s supplemented by sensored lighting in early mornings and evenings all resulting in savings on energy costs for the school district.

Puyallup School District Kessler Center – Summit Building

Entry # 381324

Category: Permanent Education Under 10,000 sqft

Company: Pacific Mobile Structures

Location: Puyallup, WA United States

Gross Size of Project: 2880 Square Feet

Days to Complete: 317

Architectural Excellence

When the Puyallup School District needed to relocate their alternative learning program, they took it as an opportunity to entertain their curiosity with a permanent custom modular building. Pacific Mobile Structures provided a 2,880-square-foot building and placed it just a few hundred feet away from the Summit Building at the Kesler Middle School next to a parking lot. The exterior of the building features a shed roof, high-end metal siding, covered entry with a half wall for a restricted view, customized fiberglass windows, and external HVAC screening. The interior of the building features an open hallway displaying an architecturally and acoustically sound cloud T-grid ceiling. After the completion of their first custom modular building, the Puyallup School District was very pleased. Now, when future expansion needs arise, they know they can turn to modular construction to get the job done.

Technical Innovation & Sustainability

The building features a two-hour fire wall in lieu of sprinklers. As a result, a plenum wall was utilized so that the two-hour fire wall was not penetrated with the outlets and low voltage.

Cost Effectiveness

In the case of this project the school district did not want to pay for sprinklers. Instead, they opted for a two-hour separation fire barrier providing protected compartments where students and staff can safely exit the building in the event of a fire. Additionally, the box sizes were maximized on this project, and the interior building heights were value-engineered. The foundation was mechanically vented.

Charlotte ISD Middle School Cafeteria and Kitchen Facility

Entry # 382590

Category: Permanent Education Under 10,000 sqft

Company: Ramtech Building Systems

Location: Charlotte, TX United States

Gross Size of Project: 5704 Square Feet

Days to Complete: 399

Architectural Excellence

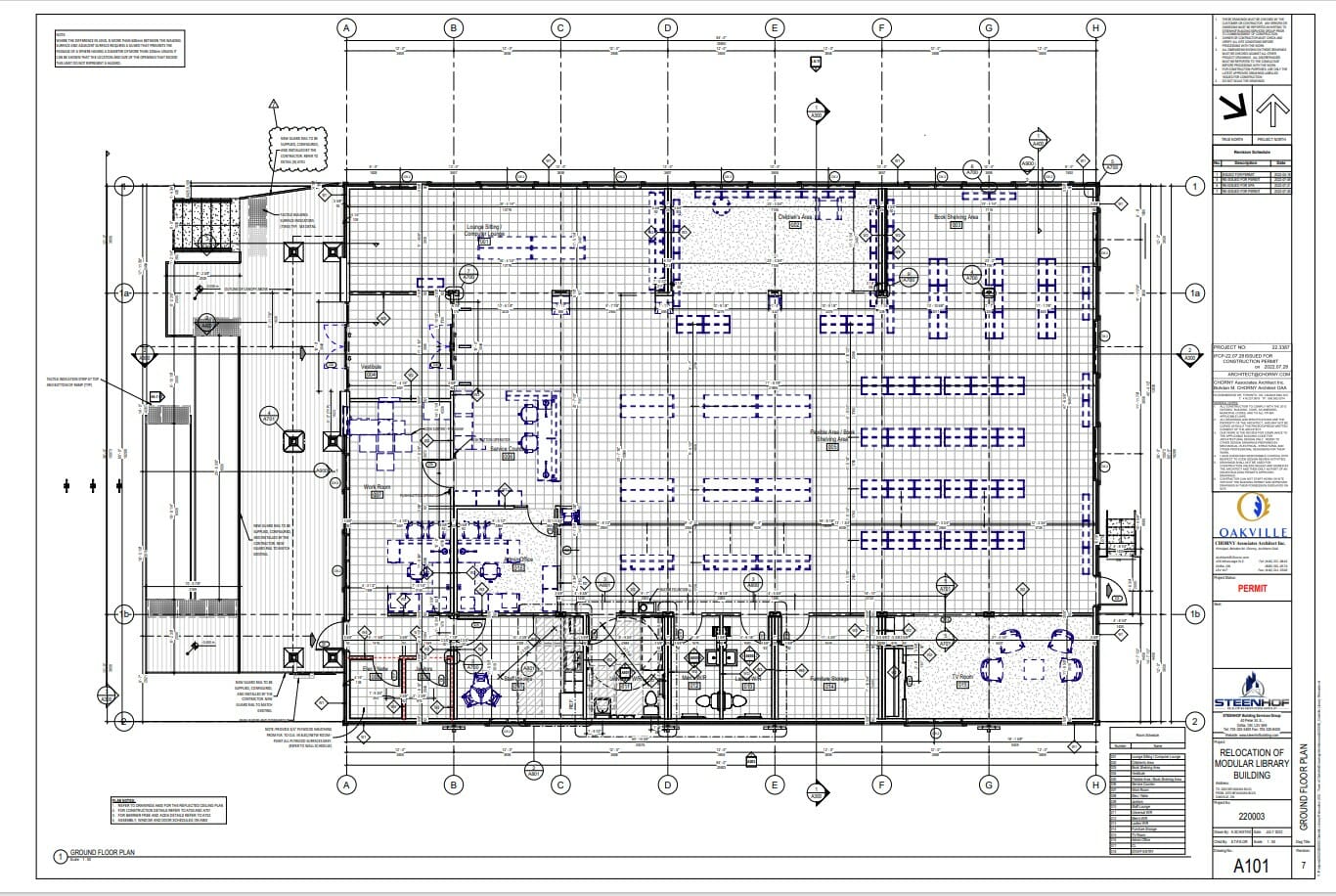

Using design-build project delivery, Ramtech partnered with Texas-based Bannister Engineering and Cosper & Associates to develop both a cafeteria and multiple classroom building using our slab-on-grade permanent modular construction process. Ramtech’s in-house design team generated the floor plans and exterior elevations, with Bannister responsible for all the civil designs and Cosper providing the kitchen design. The cafeteria/kitchen building features a full-service kitchen, walk-in refrigerator and freezer, food serving area, seating for 200 children, bathrooms, and an administrative office. Ramtech’s design team developed an exterior look utilizing a combination of light EIFS and a brick wainscot with dark brown doors and trim, gutters, and railings for contrast to complement the look of the existing structures. The interiors feature light, warm colors for the walls, tile flooring, and wainscot, while incorporating the yellow and maroon school colors in the striping and signage.

Technical Innovation & Sustainability

Ramtech’s innovative slab-on-grade permanent modular construction system was used to provide grade-level entry for both of the buildings and to allow for the clear span approach to the cafeteria building without the need for structural columns invading the interior space. Both buildings in the project were installed on Ramtech-engineered concrete slab foundations, that included belled piers drilled to a depth of 25 feet. Due to a fast-falling compound slope and confined area created by the fire lane requirement for the classroom, additional geotechnical and structural engineering input was necessary to design a retaining wall for the building foundation. This required excavating for an increased footing size and a 12-inch-thick wall to support the building slab. At the request of the customer, the approximately four-foot-tall retaining wall was left as finished concrete in lieu of using an EIFS or masonry finish.

Cost Effectiveness

While no sustainable rating system was applied, the School District wanted to incorporate as many sustainable features as their budget would allow, particularly those which would keep operating costs low as possible in the Texas summer heat. The building was designed for compliance with the 2015 International Energy Conservation Code. Insulation values incorporated into the structure were R-30 for the floors, R-21 for the walls, and R-30 for the roof. An Energy Star ™ 60 mil white-on-black EPDM single ply membrane roof was installed to take advantage of its high solar reflectance index (SRI) to aid in heat reflectivity. The HVAC consists of zoned, high efficiency 208V three-phase roof mounted package units rated at a 17.6 SEER minimum. The interior and exterior lighting is provided by 120V LED fixtures throughout the buildings.

Sierra Preparatory Academy

Entry # 382372

Category: Permanent Education Under 10,000 sqft

Company: Silver Creek Industries, LLC

Location: Santa Ana, CA United States

Gross Size of Project: 6384 Square Feet

Days to Complete: 93

Architectural Excellence

Utilizing a design assist project approach allowed the design architect and the modular building design team to collaborate on design considerations during the early in the design process to ensure the modular construction systems selected would support the design intent. The project consists of two structures which each house two Pre-Kindergarten classrooms. A separate modular restroom building was provided to serve the adjacent playground. Each classroom contains student restroom facilities, ample classroom equipment storage and an additional storage room for outdoor learning and play equipment. The buildings’ exterior is covered with a mixture of fiber cement siding panels and multi-color vertical metal siding panels to create a striking architectural presence. The building interior features large windows, and clerestory windows, to provide abundant natural light in every educational space. The classrooms utilize a curved roof and ceiling which provide ceilings as high at 14’-0".

Technical Innovation & Sustainability

To meet the project requirements while providing a unique architectural form a project specific module design was utilized. The module widths vary from 10’-0” to 12’-0” and the module lengths vary from 32’-0” to 43’-0”. The curved roof portion of the building utilizes modules that are approximately 16’-0” tall. A light weight concrete floor system was poured the in the factory for all modules. High efficiency LED lights with occupancy sensing controls and automatic daylighting controls were used in all spaces. Manual dimming controls were provided for all classroom lighting to allow the teachers to adjust the light levels for specific learning exercises. Wall assemblies separating classrooms and adjacent spaces were designed to provide acoustic separation for sound mitigation. Low-VOC materials were used throughout the project to provide a healthy learning environment. Low-flow plumbing fixtures were used throughout the project.

Cost Effectiveness

Based on previous successful modular projects the project owner determined early in their planning process that modular construction was the most cost-effective construction method for their project. By utilizing off-site construction, they were also able to realize significant schedule advantages as compared to traditional construction methods. During the design process the interior spaces were carefully planned to maximize the work that could be performed in the factory wherever possible. The restroom facilities were designed and located to be fully contained within a module to allow those spaces to be completed in the factory. Panelized exterior finish systems allowed the modules to be delivered with a majority of the exterior finish pre-installed.

Upper Lake Elementary School

Entry # 382358

Category: Permanent Education Under 10,000 sqft

Company: Silver Creek Industries, LLC

Location: Upper Lake, CA United States

Gross Size of Project: 9223 Square Feet

Days to Complete: 308

Architectural Excellence

The project consists of a kindergarten classroom building, administrative building and library building. The classroom building contains 4 instructional classrooms, 2 workrooms, collaboration central core area, student restrooms, and support spaces. The administrative building contains a lobby, 4 private offices, central work area, nurses office, and restrooms. The building exterior features a stucco exterior finish with accent colors, deep overhangs, and storefront window and door systems. Sloped suspended ceiling systems are used through the classrooms and library to maximize the interior volume. All occupied spaces features abundant glazing or tubular skylights to provide natural lighting. All classrooms have direct access to the central core which is used for small group learning and collaboration.

Technical Innovation & Sustainability

To meet the project requirements in the most cost-effective manner possible a mixture of standard and custom module sizes was used. All modules utilize a custom roof frame design to meet the client’s requirement of a roof slope to match the adjacent structures. Uneven module lengths were used to create the 10’ wide central core which runs the length of the kindergarten building without obstructions. All classrooms utilize windows to provide natural daylighting and tubular skylights are provided for additional natural lighting. High efficiency LED lights with occupancy sensing controls and automatic daylighting controls were used in all spaces. Manual dimming controls were provided in all occupied spaces to allow the educators and administrators to adjust lighting levels for specific tasks. Wall assemblies were designed to provide acoustic separation for sound mitigation. Low-VOC materials were used throughout the project to provide a healthy learning environment.

Cost Effectiveness

The project owner determined early in their planning process that custom modular construction was the most cost-effective construction method for the construction of their project. By utilizing off-site construction methods they were also able to realize significant schedule advantages as compared to traditional construction. During the design process the interior spaces were carefully planned to maximize the work that could be performed in the factory. The restroom facilities were designed and located to be fully contained within a module to allow those spaces to be completed in the factory. Utility system routing was designed to maximize installation in the factory. The mechanical system was design to utilize interior packaged heat pumps which are placed in dedicated mechanical rooms which allowed the mechanical system to be substantially completed in the factory.

Atlantis Charter School

Entry # 379228

Category: Permanent Education Over 10,000 sqft

Company: Black Diamond Group

Location: Fall River, MA United States

Gross Size of Project: 19650 Square Feet

Days to Complete: 263

Architectural Excellence

The modules were arranged to provide a central corridor running the length of the building with a main entrance door in the middle on the front with a ramp and steps. Each end door on the corridor also had a handicap egress ramp connecting to the front walkway. The building contained a central IT closet/mechanical room to house the buildings IT system, sprinkler and water service.

Technical Innovation & Sustainability

The building features a roof structure that was designed to support a future Solar Array to power the building and a Radon Evacuation System in the crawlspace. The building was designed with an underground recharge trench to disperse rainwater coming from the roof. Its purpose was to maximize permeable surface area to prevent surface water. The potable water system was designed and outfitted with backflow preventers on all faucets and taps along with a primary system backflow on both the potable water and factory-installed sprinkler system. Brightstat Wireless HVAC Controllers were tied into the main building’s Energy Management System and outfitted with ERV’s to increase efficiency. The Fire Alarm system was tied into the existing building and had built in Mass Notification for “Active Shooter” and other system notifications as determined by the school’s management team.

Cost Effectiveness

One option that we designed and installed for the owner was the use of energy efficient Heat Pumps with hot gas reheat coils for dehumidification control. The building is located on the coast so controlling the high humidity was a concern for the owner. The heat pumps are also connected to the schools Building Automation System that integrates systems to simplify command and provide better control over comfort and efficiency.

Mackenzie State Special School

Entry # 381045

Category: Permanent Education Over 10,000 sqft

Company: Fleetwood Australia

Location: Brisbane, Queensland Australia

Gross Size of Project: 13950 Square Feet

Days to Complete: 287

Architectural Excellence

Designing Mackenzie State Special School to provide specialised learning environments for students with special needs led to a world-class architectural masterpiece. Our design team pushed boundaries to meet client requirements and provide accessible learning spaces to support school students and community. Functional and aesthetically pleasing design turned 43 modules into eight general learning areas, eight offices, two life skills areas, a therapy and sensory room and two outside learning areas to meet stringent requirements for students with disabilities. The design included sensory and therapy rooms, wide corridors, specialised bathrooms, hoist system, accessways, lighting and acoustic panels. Special organic features were included such as timber-effect screening that perfectly integrated with the leafy surrounds. The new wing provides a calming, supportive environment with complementary indoor and outdoor learning spaces to cater for more than 160 students at a time.

Technical Innovation & Sustainability

The stunning custom design and construct of a new school wing complements existing school facilities to support elementary and secondary students with special needs. Complex site preparation required cut works to provide a flush entry. The school featured dimmable lights, porthole windows, Autex acoustic panels to provide soft filtered light and calming learning environments, plus a Kleemann elevator for students with mobility issues. A full fire booster and assembly upgrade, dedicated fire and smoke shutdown terminals, AC push buttons enabling status blue light, plus a large civil package including access roads for a new carpark were all delivered. The design facilitated offsite manufacturing and assembly of modules such as fabricated deck sections with custom screening that formed part of the fire-rated solution. Controlled factory conditions ensured minimal on-site waste, environmental impacts (eg, local koala population remained protected) and reduced whole of life cycle costs.

Cost Effectiveness

Time &labor cost savings were maximised through a DfMA approach, reducing errors &standardized modules for rapid production at scale, increasing design, construction &procurement speed. The project was completed by deadline in late Jan 2022, ahead of the start of the new school year, minimising costs &inconvenience from any project overrun. Trade requirements were modelled pre-construction in 3D spaces to optimize resource mobilization. Concurrent site preparation &module construction streamlined delivery &resulted in less trades on site. A fire engineer was engaged to provide advice &overcome unique obstacles with fire rating of the permanent modular building. Environmentally sustainable design reduced the heat load & airconditioning costs for the school that operates in a tropical climate. Low emitting LED lights, fixtures &fittings also reduce ongoing costs. Durable finishes &fixtures combine to reduce cleaning &maintenance costs &reduce the whole of life cycle costs for this school

Cherokee Lane Elementary School

Entry # 382507

Category: Permanent Education Over 10,000 sqft

Company: MODLOGIQ

Location: Adelphi, MD United States

Gross Size of Project: 95827 Square Feet

Days to Complete: 710

Architectural Excellence

Expansive open learning spaces with 25-foot ceilings and extensive natural skylighting provide aesthetics that support a rich learning environment. Daylighting from large windows throughout the classrooms and offices further contribute to a bright, open atmosphere. Custom millwork in admin offices, nurse station, classrooms, etc. provides maximum functionality and attractive storage space. Colorful ceramic tile for the restrooms—installed at the plant—add charm and warmth. For this hybrid project, BIM provided seamless integration between site-built structures (monumental entrance, staircases, gymnasium, etc.) and permanent modular classrooms, open learning spaces, admin offices, etc. and allowed the exterior of colored brick, textured block, and redwood style panels—completed at the site—to create an inviting, cohesive appearance that blends beautifully with the surrounding trees of the neighboring park.

Technical Innovation & Sustainability

Custom “high-hats” were developed to provide the expansive 25-foot ceiling heights in the open learning spaces. To create higher overhead clearances in hallways, the 1st-floor modules were left “open top” so that their ceilings are created by the floors of the 2nd story modules that sit atop them. Building upon this design/engineering innovation, BIM and advanced clash detection was used to optimize the configuration of the complex overhead MEP and fire suppression piping/systems, further maximizing ceiling clearances. As noted earlier, the use of BIM enabled precise integration between site-built structures and modules built offsite. This made it possible for MODLOGIQ to start off-site construction before site preparation work began. This “head start” was critical to maintaining the original aggressive schedule, as permitting issues delayed the onset of site work. These permitting delays would have created substantial schedule issues if this had been a conventional site-built project.

Cost Effectiveness

The project was delivered on budget with minimal change orders, despite permitting delays at the site that likely would have increased expenses if this had been a conventional site-built only project. However, the potential additional costs due to delays were almost entirely mitigated through the use of off-site construction. The use of BIM increased efficiency in ordering materials to support cost effectiveness. It also allowed MODLOGIQ to purchase steel pre-cut to precise lengths, making fabrication much more efficient. All of this meant greater productivity and much less waste—which not only helped control expenses, but also enhanced the sustainability of the project.

Aspire

Entry # 380981

Category: Permanent Education Over 10,000 sqft

Company: Pacific Mobile Structures

Location: Lacey, WA United States

Gross Size of Project: 10472 Square Feet

Days to Complete: 259

Architectural Excellence

North Thurston School District needed a STEM Laboratory. Pacific Mobile Structures provided a 10,472-square-foot building to house three cutting-edge science laboratories, two math classrooms, and one robotics laboratory complete with laboratory prep areas and storage rooms. Designed to maximize the footprint based on the constraints of the property lines of the site, the interior features a generous amount of gas piping, chemical resistant countertops, gas turrets and air reels at every laboratory station, custom fume hoods, an acid storage tank, chemical storage rooms, seven emergency eye washing stations, three emergency showers and over 190 lineal feet of cabinetry and counter tops. The exterior features push-button doors, a 312-transverse hinged roof, 5/16” fiber cement panel – 4X10 sections and fiber cement lap siding with 4-inch exposure, 12 aluminum and 18 vinyl storefront windows, recessed side entries, and a rain screen to blend seamlessly with its surroundings.

Technical Innovation & Sustainability

The building features a transverse hinged roof and 11 cap trusses in 14-wide sections. Half of the building was completed in the factory, and the other half was completed on site. The lighting installed is controlled with occupancy sensors and automatic dimming.

Cost Effectiveness

A hinge roof was opted for this building, rather than a site-installed roof which would have been more costly. To maintain the quality and integrity of the building and to protect it from the elements, it was shrink wrapped to eliminate incurred costs from damage during transportation.

Alisal Community School

Entry # 387470

Category: Permanent Education Over 10,000 sqft

Company: Silver Creek Industries, LLC

Location: Salinas, CA United States

Gross Size of Project: 38116 Square Feet

Days to Complete: 254

Architectural Excellence

Due to the design assist project approach utilized on this project the design architect and the modular building design team were able to collaborate on design considerations during the conceptual phase of the project to ensure the modular construction systems selected would support the design intent. The project consists of a two-story structure which houses an elementary school campus expansion. The project features 21 classrooms, 2 special education classrooms, 2 collaboration spaces, library, counseling offices, student and staff restroom facilities, and support spaces. Due to the building location on the campus a large breezeway was incorporated into the design to provide access through the building to the east campus and west campus. A portion of the upper-level cantilevers beyond the lower level to create an outdoor learning environment. Interior corridors are providing for a portion of the lower-level and the entire upper-level.

Technical Innovation & Sustainability

To meet the project requirements in the most efficient and cost-effective manner a series of project specific module designs were utilized. The module widths varied from 6’-8” to 14’-0” and the module lengths varied from 40’-0” to 60’-0”. The module heights vary from 13’-2” to 14’-2”. Large glazed openings are provided in all learning areas and tubular skylights are provided on the upper level to maximize natural light and reduce electrical lighting demand. High efficiency LED lights with occupancy sensing controls and automatic daylighting controls were used in all spaces. Manual dimming controls were provided for all classroom lighting to allow the teachers to adjust the light levels for specific learning exercises. Wall assemblies separating classrooms and adjacent spaces were designed to provide acoustic separation for sound mitigation. Low-VOC materials were used throughout the project to provide a healthy learning environment.

Cost Effectiveness

The project owner recognized early in their planning process that modular construction was the most cost-effective construction method for their project. By utilizing off-site construction, they were also able to realize significant schedule advantages as compared to traditional construction methods. During the design process the interior spaces were carefully planned to maximize the work that could be performed in the factory wherever possible. The restroom facilities were designed and located to be fully contained within a module to allow those spaces to be completed in the factory. A split-system mechanical design allowed for interior fancoils to be installed in sound insulated closets in each classroom which allowed for nearly complete mechanical system installations in the factory.

Grandview Elementary School

Entry # 382823

Category: Permanent Education Over 10,000 sqft

Company: Silver Creek Industries, LLC

Location: Manhattan Beach, CA United States

Gross Size of Project: 16128 Square Feet

Days to Complete: 171

Architectural Excellence

The project consists of a two story structure which houses an elementary school campus expansion. The project features 10 flexible classrooms, staff lounge, student and staff restroom facilities, and support spaces. Due to the building location on the campus a pair of breezeways were incorporated into the design to provide access through the building to the upper campus and the lower campus. The stairways and elevator are accessed from these breezeways which conceals these elements within the building footprint. Large overhangs are provided along the front and rear of the building to create outdoor learning environments. The large exterior balconies are directly accessed from each classroom with traditional doors and glazed operable walls. Parapets of various heights are used to visual interest while screening the roof top mechanical equipment.

Technical Innovation & Sustainability

To meet the project requirements in the most cost-effective manner possible a project specific module design was utilized. A light weight concrete floor system was poured the in the factory for all modules. All classrooms and occupied spaces feature large glazing systems to provide natural daylighting. High efficiency LED lights with occupancy sensing controls and automatic daylighting controls were used in all classrooms. Manual dimming controls were provided for all classroom lighting to allow the teachers to adjust the light levels for specific learning exercises. Manual dimming controls were also provided for administrative spaces to allow the occupant to tailor the lighting levels to meet their needs. Wall assemblies separating classrooms and adjacent spaces were designed to provide acoustic separation for sound mitigation. Low-VOC materials were used throughout the project to provide a healthy learning environment.

Cost Effectiveness

The project owner recognized early in their planning process that modular construction was the most cost-effective construction method for the construction of their classroom buildings. By utilizing off-site construction methods, they were also able to realize significant schedule advantages as compared to traditional construction. During the design process the interior spaces were carefully planned to maximize the work that could be performed in the factory. Interior packaged heat pumps were utilized to allow for a fully completed mechanical system to be installed in the factory. The interior walls were located to allow for all of the casework to be installed in the factory. The restroom facilities were designed and located to be fully contained within a module to allow those spaces to be completed in the factory. A modular elevator tower was utilized to reduce the system cost and allow for earlier occupancy.

Frank J. Zamboni Middle School

Entry # 382592

Category: Permanent Education Over 10,000 sqft

Company: Silver Creek Industries, LLC

Location: Paramount, CA United States

Gross Size of Project: 31872 Square Feet

Days to Complete: 287

Architectural Excellence

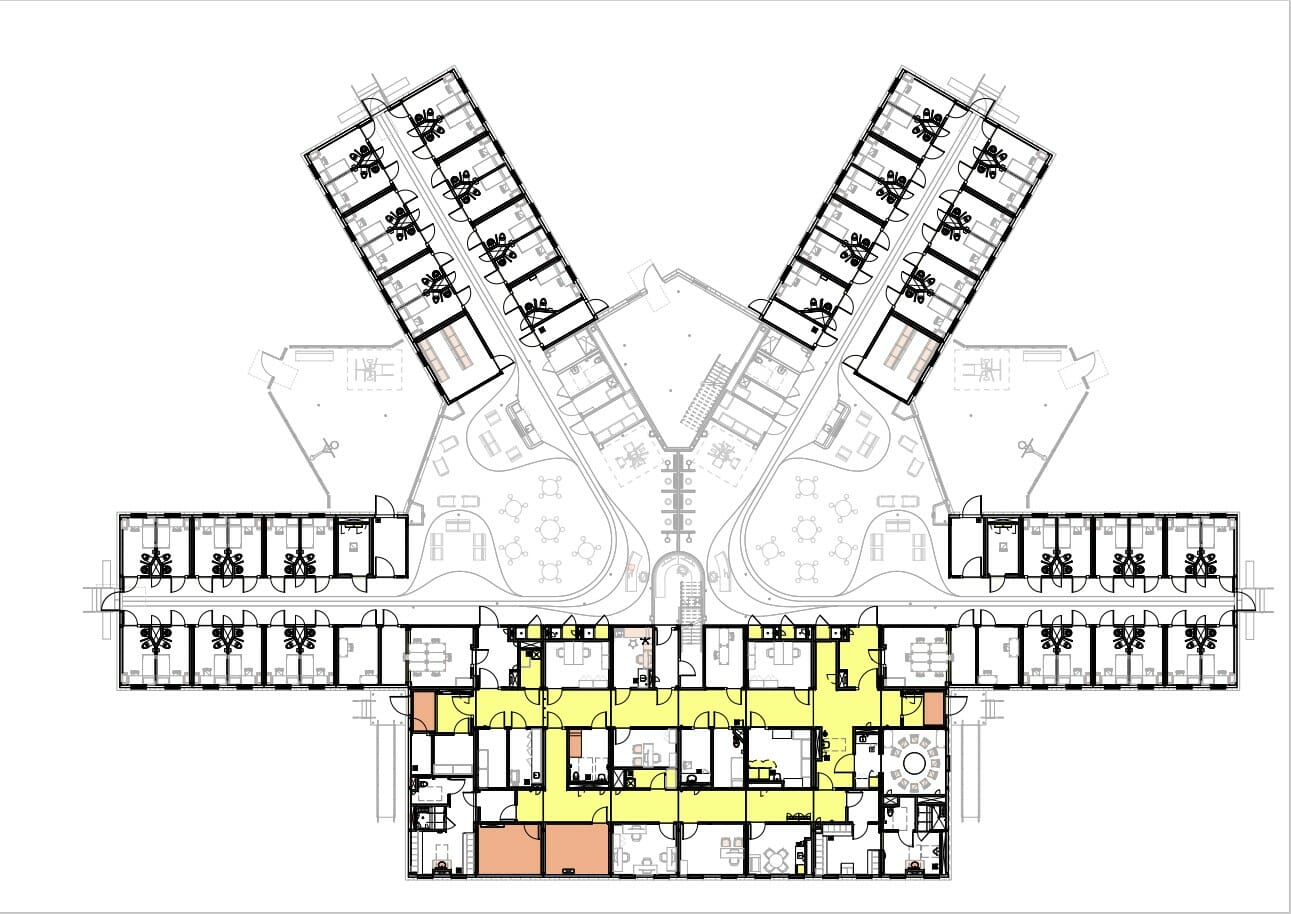

Due to the design assist project approach utilized on this project the design architect and the modular building design team were able to collaborate on design considerations during the conceptual phase of the project to ensure the modular construction systems selected would support the design intent. The project consists of a single structure which houses a large classroom building expansion, a new administrative building, a new library and the related functional spaces. The student portion of the building contains 15 instructional classrooms, a vocational classroom, a dance studio, a library, restrooms, interior corridors, interior stairs, and an interior elevator. The administrative portion of the building contains a lobby, 7 private offices, an open work area, a teacher workroom, a staff lounge, and restrooms. The building exterior is covered with stucco and feature metal panel accents which are combined with large aluminum glazing systems to provide a striking appeal.

Technical Innovation & Sustainability

To meet the project requirements in the most efficient and cost-effective manner a project specific module design was utilized. The module widths were 12’-0” and the module lengths varied from 40’-0” to 48’-0”. The module heights vary from 13’-6” to 14’-6”. The building features a dance studio with a dampened floor covering system which required the design of a series of specialized modules to accommodate the floor deck support system. A light weight concrete floor system was poured the in the factory for all modules. High efficiency LED lights with occupancy sensing controls and automatic daylighting controls were used in all spaces. Manual dimming controls were provided for all classroom lighting to allow the teachers to adjust the light levels for specific learning exercises. Wall assemblies separating classrooms and adjacent spaces were designed to provide acoustic separation for sound mitigation.

Cost Effectiveness

The project owner recognized early in their planning process that modular construction was the most cost-effective construction method for their project. By utilizing off-site construction, they were also able to realize significant schedule advantages as compared to traditional construction methods. During the design process the interior spaces were carefully planned to maximize the work that could be performed in the factory wherever possible. The restroom facilities were designed and located to be fully contained within a module to allow those spaces to be completed in the factory.

Birch Grove Montessori & University Prep

Entry # 377441

Category: Permanent Education Over 10,000 sqft

Company: VESTA Modular

Location: Rochester, MI United States

Gross Size of Project: 10780 Square Feet

Days to Complete: 263

Architectural Excellence

Birch Grove is a Montessori and University Prep School in Southeast Michigan. The school wanted to be up and running very quickly and needed a facility to accommodate. VESTA provided a 10-classroom building on a 42-acre rural property that the school needed to be designed for future expansions. The grade level set building blended seamlessly with its surroundings and gave the students a learning environment they desperately needed. During the design phase, VESTA added extra windows to the classrooms for more sunlight exposure. Furthermore, the exterior was finished with both brick and steel siding for excellent curb appeal. Upon completion of the building, landscaping and proper parking were constructed along with designing the bus loop with consideration of the future expansion of the school. The aesthetic choices were made to create the friendliest environment for the current and future students.

Technical Innovation & Sustainability

The most challenging part of this project was the location. The first issue we had to overcome was the limited access to the rural site. The site plan had to be developed in a way to minimize disruption to adjacent wetland areas. This made it challenging for the delivery and set-up crews to work around. Secondly, since the property purchased was large and there was talk of future expansion, we had to ensure the building was strategically placed on site so future buildings could be easily constructed without interruption to the current building. These issues are not typical for our standard classroom projects making this a unique case. The site planning also had to consider the future expansion and access for easy delivery installation of additional modules.

Cost Effectiveness

VESTA was able to utilize our already existing standard modular classroom design. With limited modifications, we provided a permanent style building that could be relocated if needed. Using our standard design saved us and the customer time and money in the design phase. The modular building solution saved the customer countless months of construction allowing the students to be able to move in for the 2022 school year. Considering the future construction, we provided the building in an area on the plot that saved room for other buildings. The bus loop, parking lots and utilities have also been designed with that consideration in mind, to prevent the need for any modifications and minimize site costs during the next phase.

Lehigh-Northampton Airport Authority, Braden Airpark

Entry # 379324

Category: Permanent Office Under 10,000 sqft

Company: Black Diamond Group

Location: Easton, PA United States

Gross Size of Project: 2304 Square Feet

Days to Complete: 101

Architectural Excellence

The Braden Airpark Office is a 2,304 sq. ft. office comprised of (3) 12’x64’ modular units, for housing the local Airport Authority Staff and providing a screening/briefing area for the local pilots. The building is located just adjacent to the Braden Airpark Runway. The floor plan consists of a secured entryway, staff office area, security screening, pilot break room, and rest rooms. Interior design included taped/spackled/painted interior partitions, acoustical ceiling, commercial carpet tile, welded seam vinyl flooring, large glass window viewing areas, commercial glass entry doors, gas fired central air, motion sensor lighting. The exterior design included hardi panel lap siding, shingled mansard, concrete handicapped ramp, Trex front and rear porch, stone clad skirting, motion sensor security lighting.

Technical Innovation & Sustainability

The project consisted of extensive site work to include grading, excavation, asphalt paving, concrete walkways, new electrical service, new water/sewer service, sewage pumping station renovation, storm water management, natural gas service. While the extensive site work was being performed, the modular unit was being manufactured, saving the project significant time. In addition, the building met current Energy Code requirements including, motion sensor lighting, energy efficient central air/heating, energy efficient hot water generation.

Cost Effectiveness

Per contract requirements, the site work was performed under Prevailing Wage rates. By providing a pre-fabricated modular building, the total cost of the project was reduced by up to 25% as the modular building was fabricated at standard wage rates.

Victorian Container Management Site Office

Entry # 381039

Category: Permanent Office Under 10,000 sqft

Company: Fleetwood Australia

Location: Melbourne, Victoria Australia

Gross Size of Project: 3875 Square Feet

Days to Complete: 193

Architectural Excellence

This specialized office building was custom designed for Victorian Container Management as a comfortable high-quality office space for heavy machinery operators and 25 office workers. Built in a busy industrial port precinct in Melbourne, the key requirements were a rapid build and a high-end fit out catering for each user group. The 8 modules provide a range of amenities including 7 offices, a boardroom, an internal accounts and computer room, an office lunchroom, and an operator lunchroom with mud area, kitchenette, locker room with 80 lockers, a shower, three toilets and a disability access ramp. The generous inner courtyard in the heart of the building is a unique design feature, providing a sanctuary for staff to socialise and enjoy a BBQ. High-quality durable finishes include vinyl timber-look flooring and eco-decking. The striking exterior blue integrates with the surrounding port, meeting a planning requirement for the office to blend in seamlessly with existing facilities.

Technical Innovation & Sustainability

This project’s ultimate technical triumph was the ability to coordinate, deliver and install all 8 modules on site in just one day. Design smarts included electronic tagging to ensure 8 trucks arrived in sequential order and lined up in position so cranes could drop each module according to the footing map. The modules are well insulated, allowing extremely efficient office cooling and heating. Fleetwood also installed a rainwater tank to collect greywater, significantly reducing water consumption. This project is extremely sustainable and provides the best waste and labor efficiency outcomes due to highly precise manufacture and install. Manufacturing in controlled factory conditions ensured minimal on-site works and waste, environmental impacts and reduced whole of life cycle costs. Fleetwood used BIM 360 to support informed decision making throughout the project. Trade requirements were modelled pre-construction in 3D spaces to optimise resource mobilisation.

Cost Effectiveness

The client’s brief included an urgent timeframe. Amazingly, this complex office building was delivered for $520,000 and installed on site in one day! The welcoming comfortable facility was almost entirely (90%) completed in the factory with all 8 modules completely prefabricated offsite. Fleetwood completed all onsite work in just 20 days, including decking, stairs and access ramp, detailed fit-out, electrical (air conditioning, hot water systems), and plumbing services. Durable finishes and fixtures reduce cleaning and maintenance costs and whole of life costs. We increased design, construction and procurement speed by adopting a volumetric Design for Manufacture and Assembly (DfMA) method. This uses materials already in the supply chain to optimize product manufacture and assembly. We also constrained design choices to those that could be achieved within 3.6m lengths. Our time, labor and cost savings reduced unnecessary waste, while producing the modules in record time.

Reliance Metalcenter

Entry # 382495

Category: Permanent Office Under 10,000 sqft

Company: Forge Craft Architecture + Design

Location: San Antonio, TX United States

Gross Size of Project: 8400 Square Feet

Days to Complete: 0

Architectural Excellence

Reliance Metalcenter employs the innovative and patented Vector Bloc system which is a tube-steel frame with cold-formed steel infill stud framing. The system allows for the construction of a six-sided box from interior finishes out to sheathing with weather-resistant barrier on which exterior cladding was installed in the field (in this case, a composite aluminum panel system on clips). Since the modular frames were comprised of stout tube steel, we were able to take advantage of the strength and spanning capabilities inherent in this system by breaking the dimensional barriers of conventional volumetric modular design. By stringing the modules adjacent to each other and “knocking out” internal walls, we achieved substantial open spans in the primary office space. By stacking clerestory modules on top of open span modules we doubled the interior volume where the clerestories occurred, forming double-height spaces which conveyed light and air into the primary open space.

Technical Innovation & Sustainability

The modular design and construction methods employed with the Vector Bloc system are novel and innovative. It is a robust system which was used in this case to certify an entire modular factory. By concentrating and conducting 75% of the construction inside the conditioned, controlled environment of the modular factory, QA/QC, level of craft and attention to detail was very high. This process also allowed for concurrent constructions to take place which compressed the overall project delivery schedule. Most importantly from a sustainable standpoint, the construction and labor “footprint” on-site was quite small given that most of the work took place off-site. The robustness of the Vector Bloc system also allowed for novel use of the modules themselves, allowing for large interior open spans, clerestory spaces and the ability to set the entire building 3 feet off the ground which had many advantages.

Cost Effectiveness

The real savings in this project was delivery time. The individual modules were constructed in the factory concurrent with site prep, site utilities installation and concrete foundation and flatwork. Once the modules arrived on-site, it took only about 3-4 weeks to set and stich (27) modules. Cladding and roofing finish-out took another 6 months. Had the same project been designed and constructed under conventional site-built methods, we would have anticipated a 14-16 month construction schedule as opposed to the 9-10 month construction schedule with the modular delivery. Additional inspections for the site-built portions of the project, supply chain breakdowns, long lead times for certain products, FF&E procured during the height of the pandemic and miscellaneous site constructions, especially miscellaneous steel specialty construction, added another 10-12 months to the finish-out and punchlist of the building. The building was fully occupied by mid-November 2021.

Comer Construction Modular Office Addition

Entry # 382456

Category: Permanent Office Under 10,000 sqft

Company: Modular Genius

Location: Forest Hill, MD United States

Gross Size of Project: 2408 Square Feet

Days to Complete: 168

Architectural Excellence

A local family-owned construction company needed a replacement office due to a fire that destroyed their existing office. The footprint of the new building was expanded from approximately 1,440 Sq. Ft. to 2,408 Sq. Ft. and was to conform to the existing building footprint; to include, being connected to the another “shop” type building via a connecting corridor. A 28’x 86’ building design was decided upon, where a total of four modular buildings were installed end to end to achieve the desired layout. The client wanted a residential style look and feel. Modular Genius worked closely with the client to achieve their goal. Scalloped vinyl siding was selected, stacked stone wainscot panel, a 5/12 pitched roof with architectural shingles and luxury vinyl tile flooring were added. A split HVAC system was furnished and installed on site. The air handling units were designed to fit in the roof cavity and pad mount condensing units were set up behind the building to obscure them from view.

Technical Innovation & Sustainability

Careful and efficient planning were considered prior to and during the modular building installation. The new Modular building had to be installed directly against an existing concrete connecting link which was approximately 6’x 10’. This meant that the remaining 80’+/- of the modular building had to remain square and parallel to the existing shop building once installed. Additional challenges were considered and executed; including but not limited to, flashing the new modular building at the connection corridor, coordination and planning for the site installed roof trusses and how they would work with the connecting link. Moreover, detailed planning was required for the engineering, design, installation, access and service to the air handling units, which were installed in the roof cavity (after the roof was installed on the modular building at site). The split HVAC system provides a higher SEER rating and reduction in energy costs throughout the life of the building.

Cost Effectiveness

MGI utilized its “in-house” set crew and made multiple site visits prior to the building installation to ensure proper planning and coordination when it came time to install the new building. MGI’s crew “shot the grade” and established benchmarks for the finished floor height relative to the pass through/connecting link. That time spent up front paid off as there were no issues with the connecting link when it came time to install the buildings. MGI worked with a local truss company to design, fabricate and deliver the trusses directly to site. MGI installed the roof trusses ensuring there was access to the air handling units. Then the sheathing, roofing materials and shingles were installed. MGI continued with the installation of the custom finishes to include, but not limited to; custom vinyl siding, stacked stone skirting, plank flooring, carpet tile and a custom counter/reception area. ADA access systems were installed to provide a clean and maintenance-free system.

Jordan Elementary School

Entry # 382874

Category: Permanent Office Under 10,000 sqft

Company: Silver Creek Industries, LLC

Location: Whittier, CA United States

Gross Size of Project: 2400 Square Feet

Days to Complete: 170

Architectural Excellence

The project consists of a fully modular administrative building to replace an existing site-built administrative building. The new administrative building includes a lobby, conference room, private office, nurses’ offices, staff workroom, staff lounge, restrooms and utility room. To match the adjacent existing structures this building features a steep pitch roof, stucco exterior wall finish, and large glazed openings. Large overhangs at the front and rear of building are combined with a site erected canopy to provide shade and weather protection at all entrances.

Technical Innovation & Sustainability

To meet the project requirements in the most efficient and cost-effective manner a standard 12’x40’ steep-pitch roof module design was utilized. Light weight concrete floor decks were constructed in the factory. High efficiency LED lights with occupancy sensing controls and automatic daylighting controls were used throughout the project. Manual dimming controls were provided in all occupied areas to allow the light levels to be adjusted by each user. Wall assemblies separating the private offices, conference rooms and the adjacent spaces were designed to provide acoustic separation for sound mitigation. Low-VOC materials were used throughout the project to provide a healthy learning environment. High recycled content materials were utilized wherever possible. A cool roof system, high performance mechanical equipment and high insulated envelope assemblies were used to minimize energy usage.

Cost Effectiveness

The project owner recognized early in their planning process that a modular construction solution was the most cost-effective project delivery method for their new administrative building. Based on their previous experience working with Silver Creek they were able to engage the manufacturer at the start of the design process to ensure that building was designed as efficiently as possible. By utilizing off-site construction methods they were able to realize significant schedule advantages as compared to traditional construction. The accelerated nature of a modular construction process allowed for a reduced development impact on the project site and on the neighboring home owners. During the design process the interior spaces were carefully planned to maximize the work that could be performed in the factory. The restroom facilities were designed and located to be fully contained within a module to allow those spaces to be completed in the factory.

Training Facility

Entry # 378343

Category: Permanent Office Under 10,000 sqft

Company: VESTA Modular

Location: Emerado, ND United States

Gross Size of Project: 5160 Square Feet

Days to Complete: 294

Architectural Excellence

Confidential Customer, a leading manufacturer of aircraft systems for US and allied military forces around the world, recently launched a new project. They had an immediate need for a fast track, mission critical, world-class training facility for use in training a new client. VESTA partnered with Ramtech Building Systems to meet both the budget and the customer’s schedule requirements. Full turnkey construction of a 5,160 SF, 7-module building adjoining a military base in North Dakota began soon after the harsh 2022 winter and was completed in 9 weeks. It includes (12) private offices, large conference and break rooms, multi-fixture restrooms, storage, custodial and IT Closets, and 3 entry vestibules that protect occupants against harsh weather. High ribbed steel exterior siding matches surrounding buildings for a seamless building addition.

Technical Innovation & Sustainability

During the months from January to March, North Dakota weather averages highs of 15º to 21ºF with sub-zero lows. Substantial reductions in utility costs have been achieved using high efficiency, gas-fired HVAC units with electric cooling and electronic, programmable thermostats. Further energy management gains have been the result of using 3 phase primary electrical and flat panel LED lighting fixtures. The perimeter skirting was fully insulated with R-10.4 closed cell urethane. Roofing materials have also been upgraded to 60 ml EPDM. Due to the sensitive nature of the training provided to clients in the large, 30-person Conference Room, the customer required the installation of state-of-the-art IT, video, and security systems. The new modular structure is the first, next generation product training facility of its kind and has established a design basis, timeline and fit and finish precedent for future training centers that will be provided overseas.

Cost Effectiveness

The customer’s goals for the project included 15% cost savings, and 75% less design and construction time when compared to the use of conventional construction methods. Great care was taken in the design and fabrication phases and in the selection of durable, value-based, architectural grade finishes that will meet project cost goals and reduce the cost of ownership and annual operating expenses. Exterior finishes include maintenance-free steel siding, galvannealed steel doors and aluminum deck and ramps. Break Room finishes feature custom cabinets and Daltile “One Source” quartz countertops and Shaw 20 ml LVT plank flooring. Restroom flooring is Armstrong Medintech heat welded sheet vinyl. Office, conference, and corridor areas feature Shaw vestibule quality and commercial carpet tiles with non-flow through backing. Solid core interior doors include high quality, plain sliced maple surfaces and Allegion Grade 1 hardware. Mission accomplished!

Secwépemc Child and Family Services (SCFS) Agency Office Building

Entry # 382111

Category: Permanent Office Over 10,000 sqft

Company: NRB Modular Solutions

Location: Kamloops, BC Canada

Gross Size of Project: 31000 Square Feet

Days to Complete: 433

Architectural Excellence

The 31,150 square feet, two-storey, U-Shaped wood frame modular SCFS office building was originally envisioned to be a space of gathering. Construction occurred in a timely manner and provided insulated space for the trades to work within a few months. This building boasts 77 offices, 9 large meeting rooms, a staff room, a family resource centre, a commercial kitchen, and a large courtyard. Highlighting the main entrance are log cedar columns on a designed concrete pilaster. There is a gathering space recessing into the floor, which allows for presentations and discussion platforms. The U-Shaped floor plan allows most of the offices to have a view outside or exposure to natural daylight. The main lobby is open to the second floor with glass railings trimmed clerestory, providing a sense of tranquility. Black metal windows and doors with black flashing allows the building to blend into the backdrops of the dunes and hayfields beyond.

Technical Innovation & Sustainability

The Secwépemc Child and Family Services (SCFS) Agency building was placed so that it did not interfere with the archaeological sensitive zones of the property according to the TteS Heritage Conservation bylaw. The delivery of 42 modulars was easy as the modulars were constructed at the factory 2 blocks from the site, reducing costs and greenhouse gas emissions. Providing modular construction for the building helped to reduce the amount of construction waste. As well, it provided better quality control to the manufacturing of the modules. With a team of over 150 employees, NRB Modular Solutions was able to produce one module a day on average in their heated plant. Their ability to stock materials helps reduce the amount of delivery vehicles needed for one project. Other notable features include a state-of-the-art Kaba Access Control System which was installed with a full fob access system for the first and second floors of the building.

Cost Effectiveness

This project was located less than 1 km away from our manufacturing plant in Kamloops, which naturally came with cost savings due to location and transportation logistics. The main components of the modules were built in the factory while foundation and site work were being completed, allowing the project to be completed much faster and more cost-effectively than conventional construction. Even though the modules were 75% complete before leaving the manufacturing plant, the proximity to site meant that NRB could do more of the finishings on-site, further cutting down costs. Collaboration with local contractors was a benefit for this project since they were close to or in Kamloops. Having a preferred partner for this one-of-a-kind design feature helped save time and cost. The client worked with an owner’s representative which helped streamline information and negotiations after contract. Having this representation saved time and limit costings to keep the project schedule on track.

Oak Ridge National Laboratory

Entry # 382560

Category: Permanent Office Over 10,000 sqft

Company: Satellite Shelters, Inc

Location: Oak Ridge, TN United States

Gross Size of Project: 11250 Square Feet

Days to Complete: 275

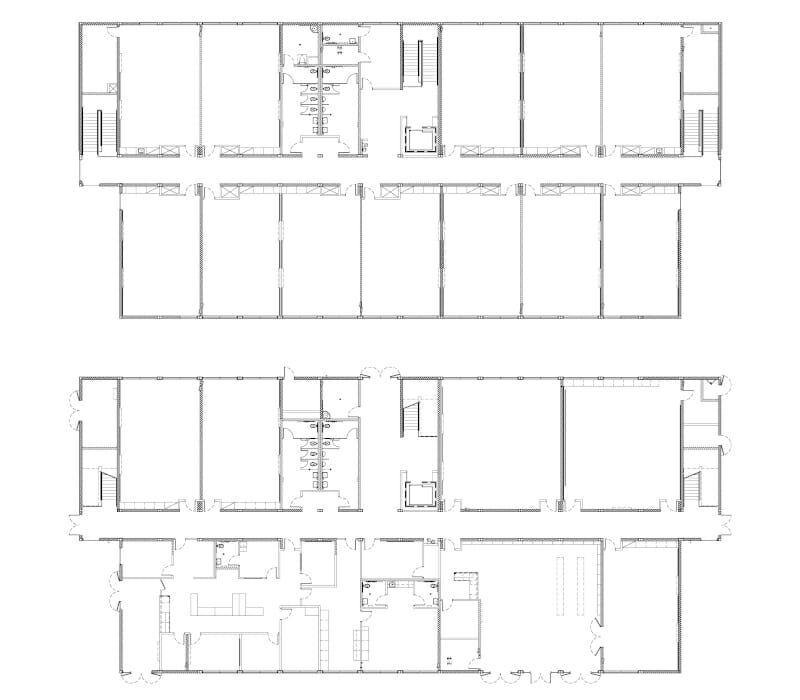

Architectural Excellence

The historical Oak Ridge National Laboratory is located near Knoxville, TN and is managed by the US Department of Energy. ORNL required a new office building to replace a demolished metal building that would maximize the confined space between two existing buildings. A two story building was designed that was comprised of (16) modules with lengths of 56’and extended on the outer modules to 66’ to accommodate the stairwells and elevator. The floorplan on each level provided individual offices, conference rooms, and cubicles as well as a breakroom and restrooms. A common entry provided a reception area with an elevator and stairwell for access to the second floor space. The building was designed with a horizontal commercial glass configuration to coordinate with other buildings on the ORNL campus. The exterior was provided with a full perimeter 4’ high parapet and Nichiha horizontally orientated panels in a neutral color.

Technical Innovation & Sustainability

To provide the most efficient and comfortable work environment the building was provided with (6) RTU’s with each unit supplying a designated zone. A poured perimeter foundation with interior piers supports the building modules. The crawl space was provided with a vapor barrier and insulated exterior walls. A modular elevator was provided by Phoenix Elevator and was lifted by crane vertical then installed within the corner of the building after the modules were in place. This installation required exact measurements to ensure that the modules floors and elevator floor aligned in operation.

This was the first time that a modular elevator has been crane installed into an interior opening of a modular building. To provide a safe working environment on the roof a 4’ high parapet was constructed on all sides of the building. The tapered TPO membrane roof has scuppers through the parapet the drain through exterior downspouts.

Cost Effectiveness

The climate in Tennessee required building specifications with 2”x6” exterior wall studs with a continuous air infiltration barrier and R-19 insulation. Rigid Insulation on the exterior of the facility provided an additional R-10 to the building envelope. The roof system was provided with R-38 insulation and finished with a TPO heat welded membrane. To achieve the desired finished product in the time frame required a combination of modular and site built construction was provided. The design started with the module CAD baselines provided by Whitely Mfg. The module configuration was shared with the other design team members who provided the final interior and exterior finishes as well as the structural design. To provide better energy efficiency the perimeter interior walls of the foundation were insulated with rigid insulation. The scope was divided to allow the manufacturing of the modules to proceed while the site work and foundation progressed simultaneously.

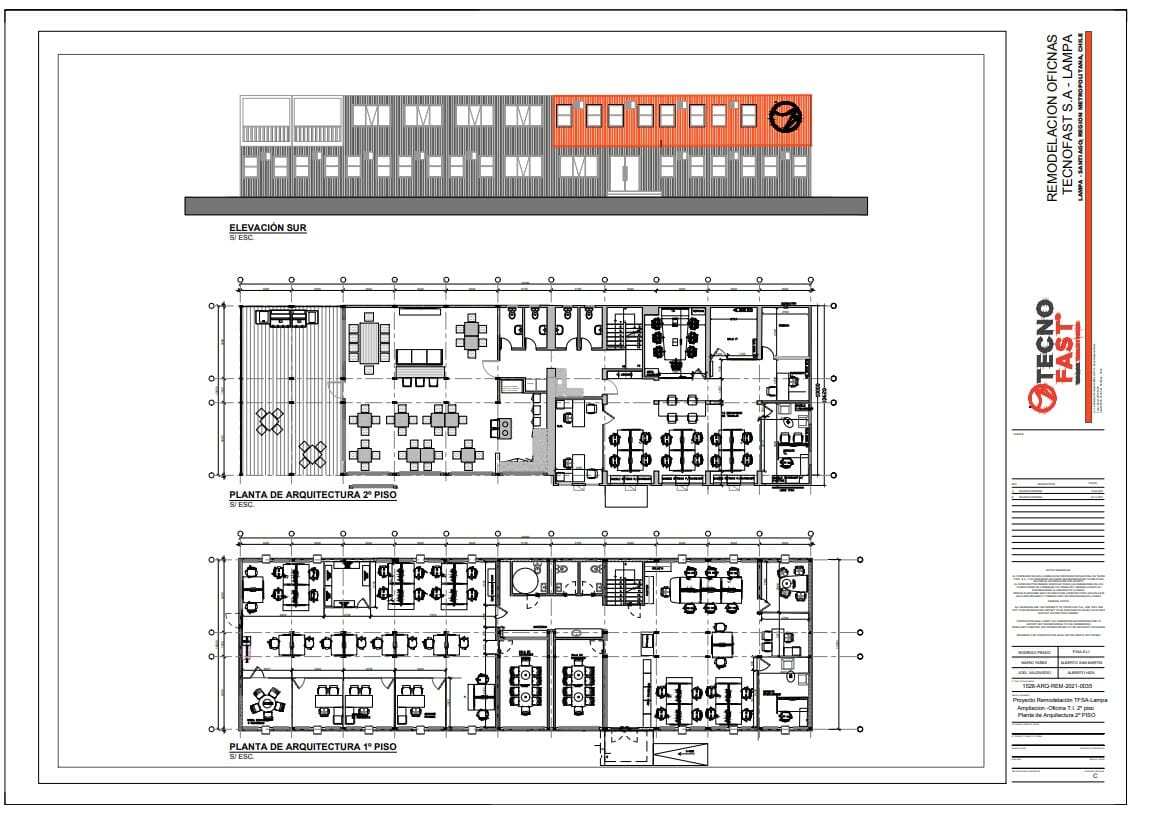

Corporate Office Remodeling

Entry # 382537

Category: Permanent Office Over 10,000 sqft

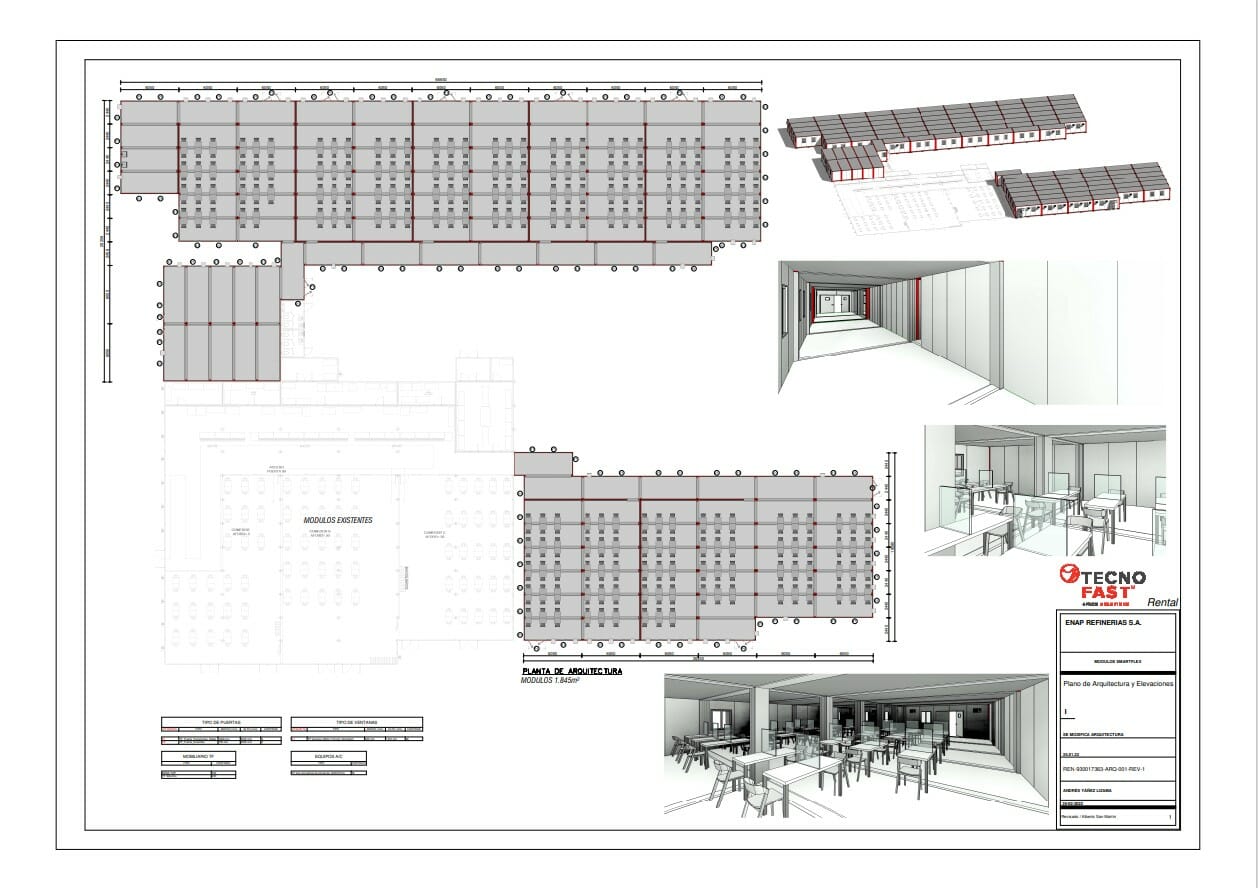

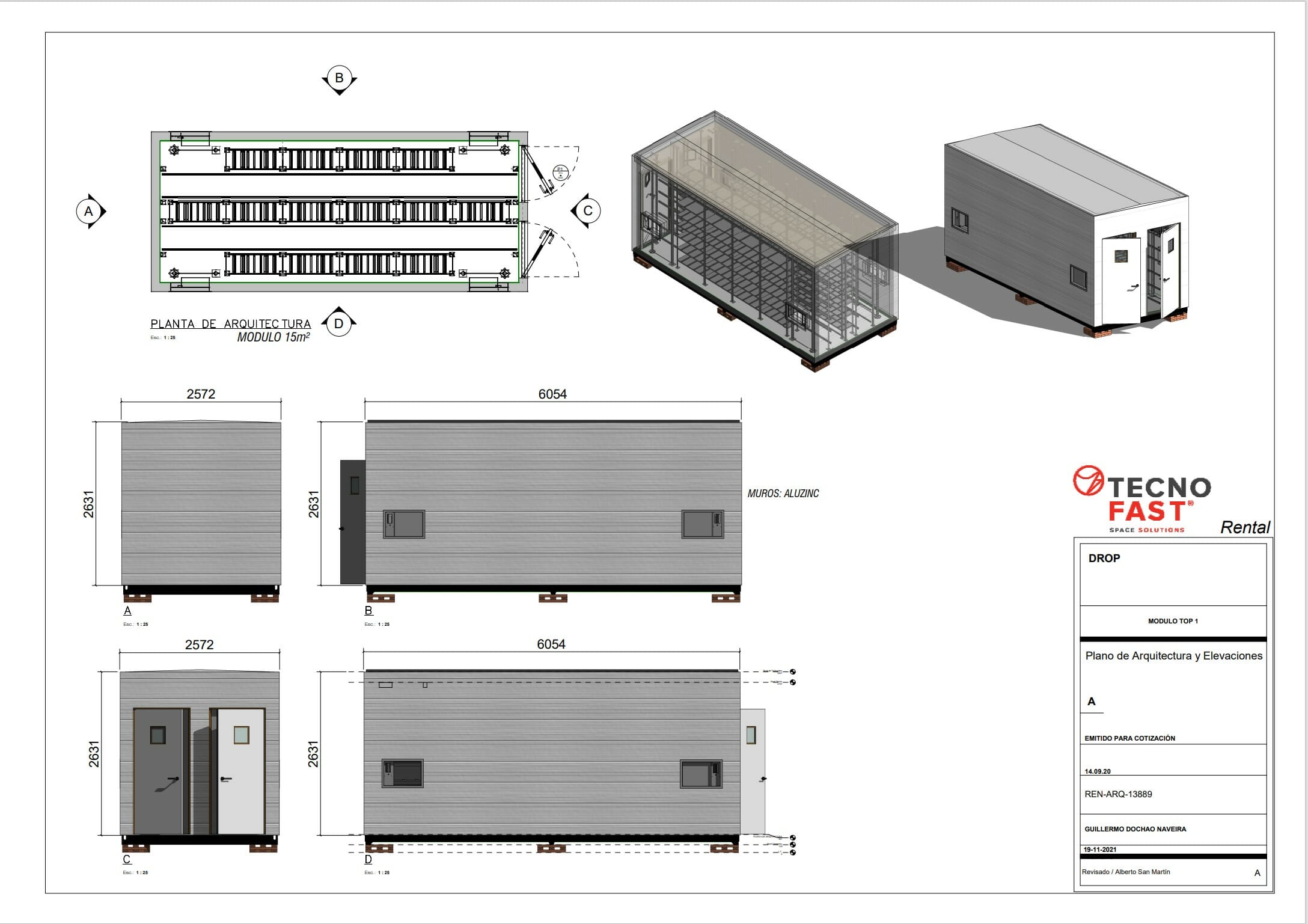

Company: Tecno Fast

Location: antiago, Metropolitan Region, Chile, Region Metropolitana de Santiago Chile

Gross Size of Project: 11668 Square Feet

Days to Complete: 365

Architectural Excellence

The new Tecno Fast corporate offices were designed by privileging the open spaces to enable communication between the different specialties, as well as light colors, in order to foster a collaborative environment and creative development to promote better interpersonal relationships between the workers, and thus yield better results in coordination between leaders and collaborators in developing highly complex projects.

Technical Innovation & Sustainability

In relation to technical and sustainability innovations, Tecno Fast applied state-of-the-art improvements in the design and construction of its new facilities. They included air conditioning and ventilation systems which allow maintaining appropriate ventilation depending on the number of people who use the offices. The implemented furniture was designed by taking into consideration the concentration of users and comfort of the people, achieving an ergonomic design adaptable to each user. Support systems for multi-screen human scale work were incorporated into each of the workstations. Likewise, a balance between natural and artificial lighting was achieved by incorporating skylights in the central area of the offices along with LED lighting.

Cost Effectiveness

The project was 100% remodeled thinking of a 25-year life span. Thus, the company's assets can be profitable over a long period of time. This is thanks to the quality of the materials used throughout the remodeling.

Culver Duck Office

Entry # 377401

Category: Permanent Office Over 10,000 sqft

Company: VESTA Modular

Location: Middlebury, IN United States

Gross Size of Project: 10536 Square Feet

Days to Complete: 884

Architectural Excellence

Culver Duck is a duck processing company that began as a hatchery in 1858. They have evolved into the only farm in North America to have earned the American Humane Certification. The company has expanded and needed dedicated administration offices to move staff into next to the processing plant. VESTA designed a two-story office that features a state-of-the-art full functioning cooking kitchen on the first floor. The kitchen is utilized for classes and demonstrations on how to cook duck for individuals as well as professional kitchen chefs. The interior was designed to be a facility with upgraded finishes to hold public presentations and a functional, friendly office environment. The exterior materials and finishes were picked to complement the existing buildings. Cedar and stone accents were added to the whole building to give a more permanent site-built office feel along with a steel standing seam metal roof and entrance canopy to match the material choices.

Technical Innovation & Sustainability

The overall design goal was to provide staff with a new and open workspace to improve productivity and an environment where the public could enjoy learning how to cook the duck properly. It was a necessity for VESTA to consider the 9’ ground slope along with the 2-story modular construction. Being the only duck farm in North America to have earned the American Humane Certification, it was important to Culver Duck to practice greener methods. The modular building solution paired well with the standards they have set for their business. Typical modular buildings would have a crawl space for utilities, plumbing and foundation. With the 9’ grade change, we were able to provide a full height, fully functional basement for access to all the building’s utilities.

Cost Effectiveness

Moving forward with a modular design allowed the time of construction to be cut from two years to one. This saved time and money for the overall construction costs. The time savings also helped get the staff into the building faster, which means better productivity and more overall business for Culver Duck. The building was manufactured at a factory within 50 miles of the job site, thereby reducing the module delivery costs and minimizing the project’s carbon footprint. By taking advantage of the natural grade of the site, we were able to provide access to the building utilities in one accessible location for ease of future maintenance.

National Institutes of Health - Laboratory for Cancer Research

Entry # 391770

Category: Permanent Healthcare Under 10,000 sqft

Company: Art's Way Scientific, Inc.

Location: Frederick, MD United States

Gross Size of Project: 5787 Square Feet

Days to Complete: 676

Architectural Excellence

The design and fabrication of the modules met the 2018 IBC/IFC, II-B design, occupancy group B, full sprinkler, lab hazard C, SMACNA, NEC, ANSI, and ASTM requirements. (1) standalone 101 sf mechanical room to house electrical equipment with transformers, switchgear & ATS. (2) units tied together to complete a BSL-2 central lab, office/admin area, restroom, cell culture, LAN room, a microscopy suite, and mechanical space. (3) units tied together to complete a BSL-3 environment with lab, change rooms, air shower, air lock, pit mounted autoclave, restroom, receiving/storage, feed area, procedure area, animal holding, and mechanicals. Units were fabricated from welding 3-1/2” square steel column posts and 18 gauge steel studs and 6” top and 10” bottom C-channels with 5/8” drywall painted 9’ interior finish. Magnesium subfloor with epoxy finish with troweled coving and roof was tapered insulation covered with EPDM. Ceilings varied with acoustical, lab, and lockable tiles in bio-seal area.

Technical Innovation & Sustainability

The customer has strict industry regulations and professional standards with record keeping of the building vivarium’s environment including humidity, temperature, air changes per hour, lighting, electrical backups, etc. These Building Automation Controls needed to be integrated into the HVAC systems and accomplished with controls that can be monitored remotely. The fire alarm system needed to be upgraded to a closed loop type A system. There was a bio-seal from the dirty to the clean side of the BSL-3 complex which made the installation of the autoclave to be an exact fit and finish and we had to add smoke & air testing to prove a fully sealed barrier for their research. Every electrical conduit needed to be sealed shut between the barriers and with lockable ceiling tiles. With fully redundant AHUs providing 100% fresh air for the environment and animals there were two heat recovery units added to the limited space which proved to be challenging along with items installed on site.

Cost Effectiveness

Units were designed with heat recovery on the north and south side of the complex to help reduce overall costs of running the 100% fresh air fully redundant air handling equipment. The autoclave was lowered down through the roof of one of the units to save time and costs. We repurposed footings and slabs from the old structure to save cost and developed some custom hold-down plates for the structural requirements. We utilized existing chilled water and steam piping on site for HVAC equipment. Compressed air, vacuum pumps, CO2 & LN2 tanks, and animal watering placement were carefully designed to ease gas tank replacements and distribution between units. AHUs were sized for future 20% over-capacity with a single pass which filtered air throughout the lab and animal areas with 99.997% HEPA-filtered air for the animal environment. Strategic planning was necessary to curb costs for the stainless-steel exhaust ductwork for the biological safety cabinets and the placement of safety showers.

Suquamish Tribal Health Clinic

Entry # 381353

Category: Permanent Healthcare Under 10,000 sqft

Company: Pacific Mobile Structures

Location: Suquamish, WA United States

Gross Size of Project: 4044 Square Feet

Days to Complete: 61

Architectural Excellence

The Suquamish Native American Tribe was inundated with community members in need of clinic dedicated to COVID-19 testing, diagnosis, and treatment. Pacific Mobile provided a 60X62 building with a 9X36 vestibule attached, totaling a 4,044 square foot COVID-19 Clinic. The building includes offices, a kitchen, and patient, procedure, telehealth, exam, consult, and lab rooms with special holding rooms for medications as well. Sound walls and extra lighting throughout complete the interior of the building. The exterior features a standing seam metal roof that had to be installed onsite due to roadway height restrictions, hardy lap siding, a pad-mounted split HVAC system, custom porch, and an added generator for backup. Final touches include color and style-matching to the scheme of the existing tribal buildings. The building site is located on a peninsula overlooking Port Madison.

Technical Innovation & Sustainability

With the site location situated on a peninsula just north of Seattle, harsh weather is a given in the winter months in the Pacific Northwest. Because of this, the building was designed with a membrane roof that would take the site rolled trusses and roofing without having to move it. This proved to be a very important innovation when the time came to install the building as there was a windstorm the team had to work through.

Cost Effectiveness

Due to the site location being nearly surrounded by water, local suppliers were utilized to ease the cost of transporting materials to the site. Hardy lap-siding was used for additional protection and longevity of a building located in the Pacific Northwest, along with a standing seam metal roof to shield the building from the abundance of rain in the region. When placing a building in this area of the United States, it’s important to go above and beyond for the building to truly be a standard 40-year building.

VA Medical Center

Entry # 376421

Category: Permanent Healthcare Under 10,000 sqft

Company: Wilmot Modular Structures, Inc.

Location: Philadelphia, PA United States

Gross Size of Project: 1750 Square Feet

Days to Complete: 78

Architectural Excellence

The layout consists of 3 modules ranging in size from a 14’x60’ to a 14’x25’ due to the tight footprint of the site and its unusual configuration. Vinyl siding was chosen for the exterior to complement surrounding buildings. Light tunnels were installed over all the cubicles in the administration department to provide natural light and reduce the number of electric lights installed in the building.

Technical Innovation & Sustainability

The installation of the building was challenging due to the site location behind other buildings and its odd shape. A crane was used to lift three modules - a 14’x60’, a 14’x40’, and a 14’x25’. The customer requested that light tunnels be installed over each cubicle in the building, so they had natural light. Motion sensor lights were added throughout the building for energy efficiency

Cost Effectiveness

The VA Medical Center has very strict site requirements. Modular construction took the construction process offsite and saved money and time by eliminating the need for oversight of multiple trades and project management for a long construction period. The 3rd party factory inspections also made it easier to go through the approval process, which saved time and money. Adding light tunnels minimized the amount of lighting they had to install which reduced utility costs.

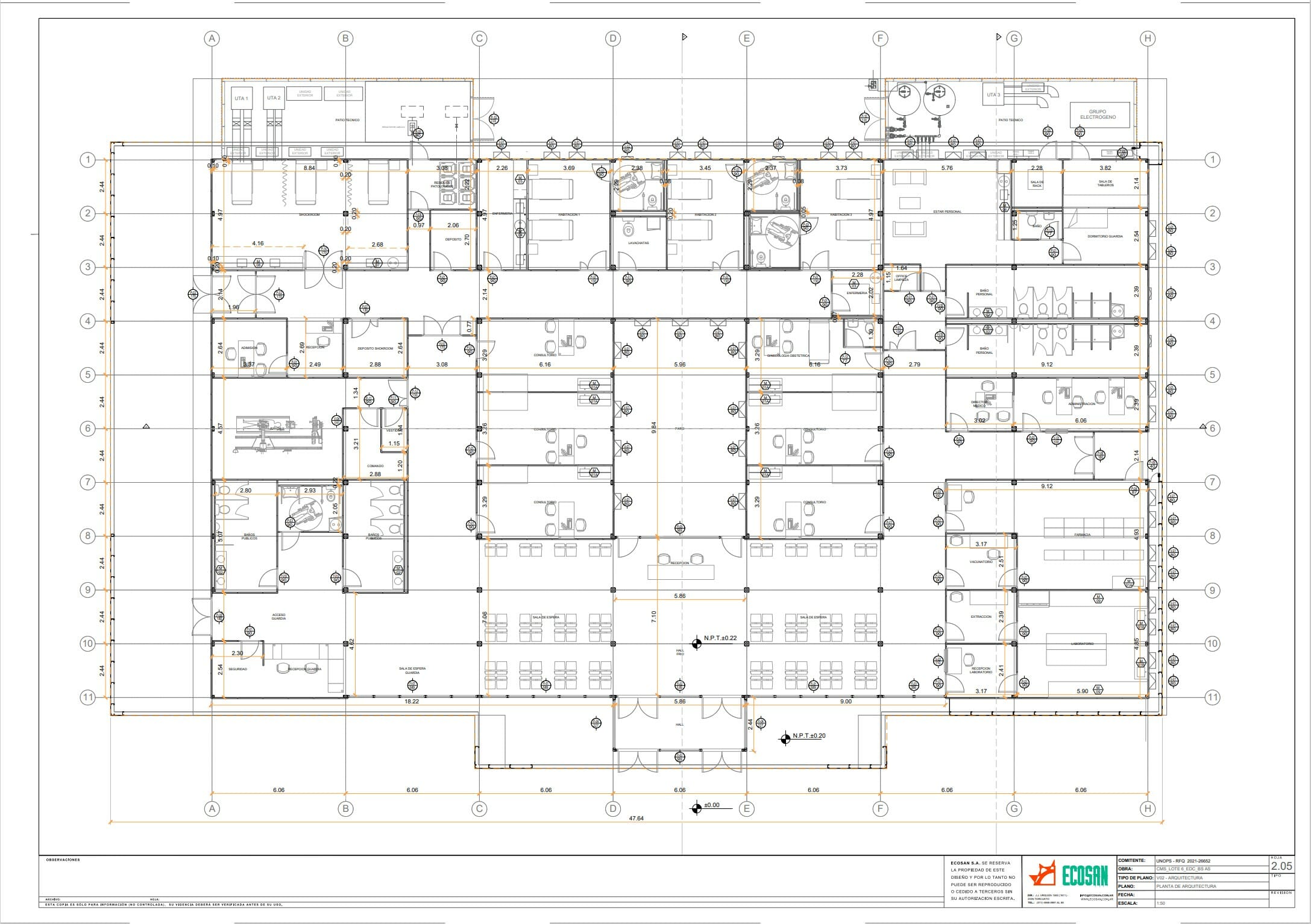

Adquisición de Centros Modulares de Salud

Entry # 399642

Category: Permanent Healthcare Over 10,000 sqft

Company: ECOSAN S.A.

Location: Cardales, Partido de Exaltacion de la Cruz, Buenos Aires Argentina

Gross Size of Project: 10980 Square Feet

Days to Complete: 53

Architectural Excellence

The building consists of a Public Area made up of: waiting room, admission offices, clinics, vaccination, infirmary, and a Restricted Access Area: monitoring room, shock-room, x-ray room, pharmacy, laboratory, public toilets , bedrooms and changing rooms for health personnel, warehouses and machine room. The building is resolved on a single floor of 10,980 ft2, made up of 66 prefabricated modules of 19'10 1/2" x 8' assembled together on site. The modules are made with a galvanized metal structure, and internal enclosures of pre-painted galvanized sheet metal thermopanels, a double phenolic plate floor and a high-traffic vinyl flooring finish specific for hospital use. The roof that covers the entire complex is executed with a structure of modular prefabricated ribs and galvanized profile belts and a highly insulated prepainted galvanized sheet metal thermopanel roof.

Technical Innovation & Sustainability