ANC Modular Everlasting Tree School

Company: ANC Modular

Location: Hagersville, ON, Canada

Gross Size of Project: 14,079 Square Feet

Days to Complete: 147

Award Criteria

Architectural Excellence

ANC Modular worked closely the Six Nations community and Indigenous architects to develop a design that embodies the highest standards of quality, efficiency, and sustainability.

We incorporated sustainable design elements, including energy-efficient windows, high-performance insulation, and low-carbon concrete.

This collaboration ensured that the cultural significance of the school was reflected in every aspect of the design.

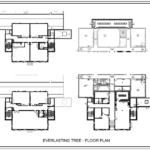

The 3-floors comprised of 31 modules, of which 24 were dedicated to classrooms, meeting rooms & common areas, with large expansive spans.

A creative approach was taken with the design of corridors and stairwells, using distinct steel frames paired with concrete slab corridors.

The shared frame configurations of elevator shafts and mechanical rooms enhanced structural integrity, maximizing ceiling height within corridors and maintaining occupiable space in classrooms.

The unique design elements included cantilevered 2nd and 3rd floor modules to boost classroom sizes.

Technical Innovation & Sustainability

The client wanted to be as sustainable as possible, and to eliminate as much need to burn fossil fuels as possible, so we designed the building to use all electric heating and cooling, to position them to expand into an alternative energy solution in the future.

To ensure that this design was energy efficient, we incorporated a wall system of R40, and a roof system of R60+, with heat pumps and HRVs in the mechanical system.

All concrete both in our modules, as well as the footings and foundations, were poured using a low carbon concrete, eliminating 50% of the carbon impact on the environment.

In the modules, we used a Broze Low Carbon and Lightweight Carbon mix design, which in 2022, won the Ontario Concrete Association award for Innovation.

Cost Effectiveness

Using offsite manufacturing methods and processes allowed us to use efficiencies to cut back on skilled labor hours for the overall duration of the project.

This labor is typically the most expensive part of a construction project.

By cutting back on the labor required, and making this more efficient, we were able to reduce the overall costs that it would have otherwise taken to complete this project.

Further that, because of the expedited timelines, we were able cut back on the costs of general conditions that are usually associated with on-site construction.

See More Awards of Distinction Winners

To view all our current honorees, visit our main Awards page.