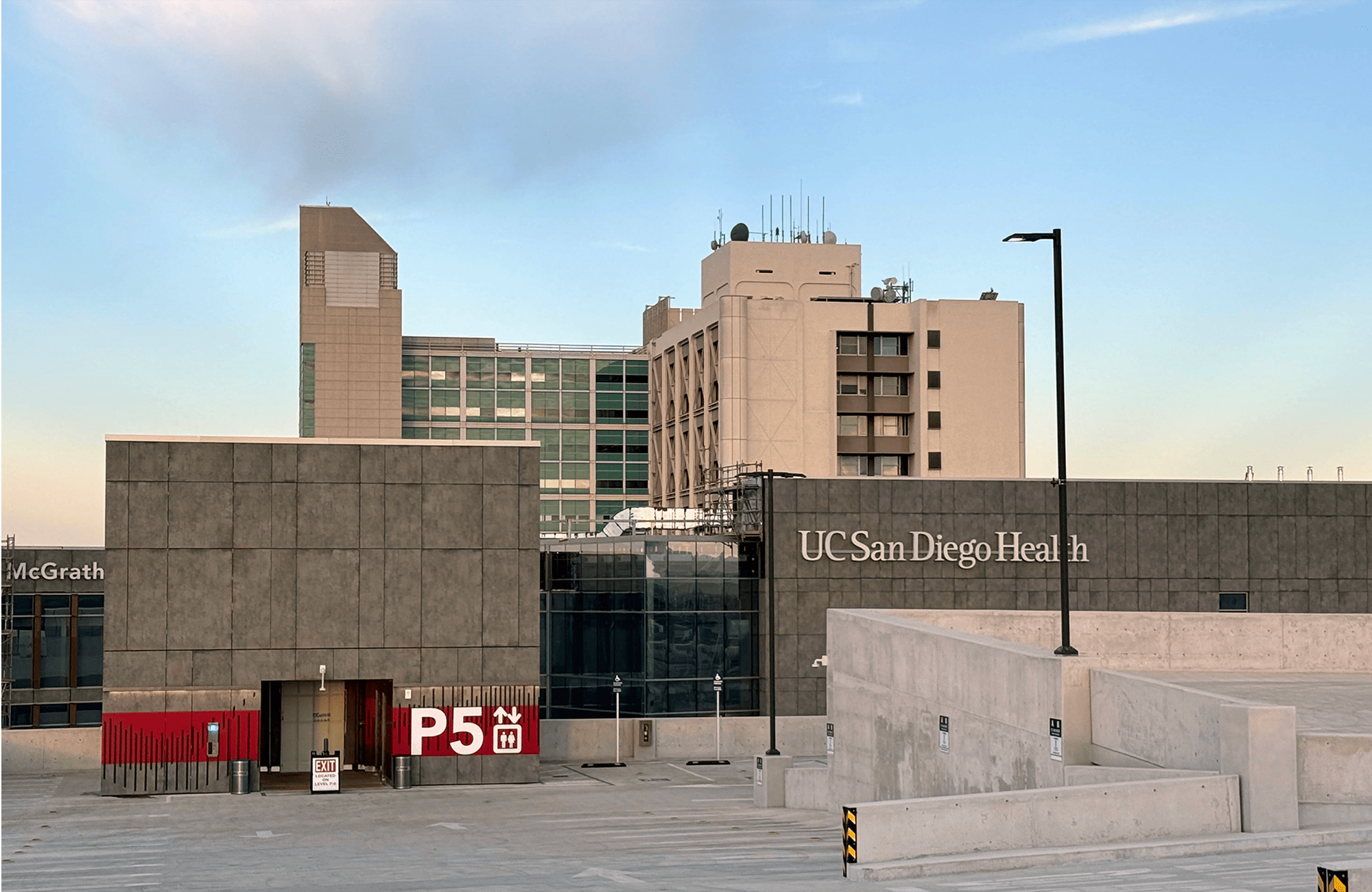

UCSD Hillcrest Campus Parking Garage Elevators

Company: Phoenix Modular Elevator

Location: San Diego, CA, USA

Gross Size of Project: 3,600 Square Feet

Days to Complete: 49

Award Criteria

Architectural Excellence

Phoenix Modular Elevator provided four 9-stop elevators for the new UC San Diego parking garage which serves the McGrath Outpatient Pavilion as part of the Hillcrest Campus redevelopment project. The garage features a sleek, modern design with materials and finishes that complement adjacent campus buildings. The elevator interiors are equipped with stainless steel wall panels, a matching ceiling, and LED lighting, creating a clean, modern, and durable aesthetic suitable for high-traffic use. These interiors reflect the project’s focus on both practicality and style, tying the elevators to the broader aesthetic of the parking structure and the campus.

Technical Innovation & Sustainability

The modular elevators showcase innovation and sustainability through efficient design, construction, and operation. Prefabricated off-site as complete units—including the shaft and elevator components—they allow for quick on-site installation, reducing construction time, minimizing disruption, and ensuring high performance and safety standards.

The modular approach minimized on-site waste and lowered the carbon footprint compared to traditional methods. The only waste generated was wrapping material, while wood cribbing and metal shipping brackets were recycled, and all other materials remained with the elevator. Fast installation was crucial to the project’s success; despite permanent power not being available until mid-February, beneficial occupancy was achieved by March 23, 2024. This timely completion enabled demolition of the existing garage to proceed on schedule, ensuring the phased project stayed on track.

Cost Effectiveness

The modular elevators significantly contributed to the project’s cost-effectiveness through offsite construction, which reduced labor costs and eliminated delays caused by weather and on-site power issues. All 12 towers for the four elevators were installed in just six working days, compared to the roughly four weeks required to construct CMU shafts. Within five weeks of obtaining permanent power, the elevators were inspection-ready—far faster than the 12-week minimum for traditional methods. Additionally, the factory-controlled manufacturing process ensured higher quality and consistency, minimizing rework and further contributing to cost savings.

See More Awards of Distinction Winners

To view all our current honorees, visit our main Awards page.