Hermeus Office and Engine Testing Center

Main Category: Modular Building Design

Company: BMarko Structures, LLC.

Location: Atlanta, GA

Building Use: Office Space and Engine Testing

Gross Size of Project: 3549 Square Feet

Days to complete: 198

Award Criteria

Architectural Excellence

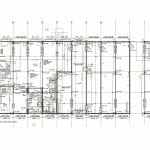

The complex consists of (13x) 40' high-cube shipping containers. Nine of them are on the first floor and four were utilized to create the second floor. Within the structure, there is one large working area, a breakroom, 2 unisex bathrooms, a public conference room, a private conference room, multiple private offices, an engine testing room, and multiple storage rooms. There is a dramatic wall of glass at the building side entrance that continues from the bottom container module to the top of the second story container. This allows much of the common areas on the first and second floor to experience a significant amount of natural daylight. The building has a very open flow that continues onto the viewing decks located on the first and second floors which allow employees to enjoy views of the planes landing and taking off at the airport. The utilization of shipping containers also ties into the aesthetics of the airport where the building is located.

Technical Innovation & Sustainability

Hermeus is a venture-backed startup with the long-term vision of transforming the global human transportation network with Mach 5 aircraft. At Mach 5, travel is not just supersonic, it's hypersonic. At these speeds – over 3,000 miles per hour – flight times from New York to London would be 90 minutes rather than seven hours. Because speed is Hermeus' calling card, they needed an office fitting those characteristics. Thanks to great project management, while the contract was signed in October of 2020, their onsite construction consisted of only 33 days between breaking ground and testing their first engine at the facility in August 2021. One unique design aspect that cut down on the onsite work was the use of shipping container base frames for the actual decking structure. The deck tied into the containers with twist locks at the ISO corners. This really expedited the completion of the decks to meet their compressed deadline.

Cost Effectiveness

Whenever possible the interior mating walls were left to be the existing container corrugation. This created the aesthetic the client was looking for and eliminated the need for framing and drywall. Another area that provided cost savings was utilizing the shipping containers for the decking structure. The extreme rise in material costs and labor made the use of shipping containers a much more economical solution for the deck structure. The mate line connections were designed in such a way that the building can be relocated should the client decide to move in the coming years. Lastly, adequate daylighting should help the client keep their heating bill much lower in the winter months.

See More Awards of Distinction Winners

To view all our current honorees, visit our main Awards page.