Best Practices—and Processes—of Modular Construction Projects w/ Catalyst Offsite [podcast transcript]

Best Practices—and Processes—of Modular Construction Projects w/ Catalyst Offsite

Blair Davies, P.Eng, COO of Toronto-based Catalyst Offsite, joins the podcast to discuss the processes necessary to properly plan and start a modular building project.

Blair also talks about common mistakes that first-time modular building developers make and shares best practices learned over decades in the building industry.

John McMullen

Hello and welcome to Inside Modular: The Podcast of Commercial Modular Construction, brought to you by the Modular Building Institute.

Sponsored ad

With a compact footprint, variety of unit options and seamless system management, City Multi-Variable Refrigerant Flow Zoning Systems from Mitsubishi Electric Train HVAC US are a one-stop solution for modular projects. With efficient operation and the ability to connect to commercial ventilation equipment, third-party systems, and comprehensive control solutions, City Multi-VRF can help you meet energy and performance goals on your next project.

From off-site development to on-site assembly, you can trust our manufacturer-level support to guide you from system selection to design to startup no matter the application.

To learn more about our offerings visit Mitsubishipro.com

Welcome, everyone. My name is John McMullen. And I'm the Marketing Director here at MBI. Today, I'll be speaking with Blair Davies, Chief Operating Officer at Catalyst Offsite. Blair is here to talk about the modular construction process and the specific steps that need to be followed for project success. Blair, thanks for coming on.

Blair Davies

My pleasure, John, thanks so much for inviting me.

John McMullen

So tell me about yourself. What's your background? And how did you get into the modular construction industry?

Blair Davies

Well, it's a bit of a long winding road, which happens in life. I'm an engineer, I've been growing technical engineering based businesses, my whole career that involves starting off in the building industry. And then 20 years in tech dealing with electronic aerospace and automotive, very tight designed for manufacturing processes and supply chains.

And then I re-entered the building industry in about 2005 and fell myself naturally into the facade business, we own another company that does that. And in that world, combining engineering and architecture just fit like a glove.

One of the things that I saw happening, though, was the construction process was wrong. And it was wrong, because I saw being done right in the manufacturing world. So I've always been trying to find that that tight collaboration, the design for manufacturing, the you know how the supply chain meets customer needs, blah, blah, blah. And I have a lot of interest in prefab wall systems with facades on them. And it's being done around the world. So I'm very intrigued by that area.

So then I, I went to see Julian Bowron, and maybe a couple years ago, and I showed him what I wanted to do. Julian's an inventor type, and he says, "I can do that. But I got something more important." And he started showing me what he's doing and modular and full volumetric modular. And wow, my, my eyes lit up. And I'll explain a little more as we go forward here. Sure.

John McMullen

So tell me about Catalyst Offsite, it's a relatively new venture, is that right?

Blair Davies

Yeah, it's actually started in 2001. We started another business with a frame system in 2020. And in 2021, we the purpose of catalyst off site is to help people transition towards a world class off site, manufacturing and construction. So we, it's a bit of consulting, but I kind of hate that word. We really roll up our sleeves, were trying to help people get supply chains, design factories, so you know the whole process. And we've built up some really strong content in equipment budgets. Whew, you know, HR or darts, QC processes, supply chain, selections, the whole game from all the way from concept to delivering to a job site. And then as well as just providing knowledge.

We are experts in design, and manufacturing of very high precision production equipment, things like welding fixtures and jigs. And, you know, these are large scale, high precision systems.

John McMullen

So with all this experience, that you have all these knowledge that you've gained, you've been around the industry for quite a while now, your company is fairly new, as you said, but how do you help those who are new to modular we're talking about traditional owner developers, for example, how do you help them wrap their heads around the concept of modular construction? What are you saying that helps them make that leap?

Blair Davies

Well, we'll talk about process in a couple minutes. But I guess I'll start off with the some of the key aspects, you say wrap your head finding, it's like turning their head around 180 degrees to be honest with you.

So first of all, the you're starting with the design of a product, the product is the module. And design is done up front and is designed heavy, you're going to leverage that design over a lot of buildings. So all that work is like an investment. Production is really what comes from doing that design correctly. And you know, design done right, frankly, means that there really are no decisions on the factory floor, things come together the way they were designed. And we're using four parametric design systems.

So this isn't CAD, this is the whole, really understanding what you're going to be put together, then building design, it has to do with taking those products, and in a creative way, doing the architecture around high precision modules. And we like to say, you know, we use the word simply precise, or simple precision. And, and that means that in essence, precision is free. If you get the design done, right, you either make or buy the parts to precision of, you know, way down to a millimeter or so when these things come together. And when they're put together in the factory and stacked on the job site. Everything fits.

And so you have really, really successful cost, high throughput, simple supply chains, implied quality, a repeatable process, and very highly constructible process. So, you know, it is all about getting the design right at the front. And frankly, that's what I saw in other industries. So I feel like I'm just applying stuff that's already known.

John McMullen

So once you've got their heads turned around 180, we'll go with we'll go with your metaphor. What's the process? How do you break down for developers and GCs who are new to modular? How do you break that down? What needs to happen?

Blair Davies

Well, what I'll describe to you is a very schematic-level process, of course, we're the folks that try to help people get to this level. So you can't really lay it out like a cookbook, everybody's different.

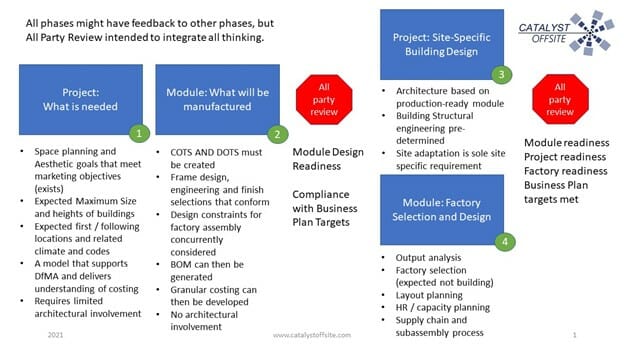

But first of all, you start off with a really high, highly cross functional team. To figure out what you really want to do in this project, you're going to look at space planning, aesthetic goals, what's the target market, what's the revenue and cost targets that you're trying to hit? What are the kind of expected building sizes or heights that you're going to hit? What are the climate and building code expectations. And, and to some extent, you're really just trying to put some limits on what you're trying to accomplish as a business. And as much as business as it is technical. And then you let all the cross functional team go away. And a small lean team designs a module to hit that expectation. And we, we choose commodity parts off the shelf and go and actually get the parts physically get them, make sure their data sheet matches what the thing is in your hands, and really drive it down to all the way down to the fastener and get really, really precise about the cost.

We also look at all the design expectations, and we get all the way down to things like how doors are gonna fit and how the washroom is going to work and all the details, the floor, the height, the ceiling, the windows, the facade, all these types of details that we'll be using over and over and over again, that helps again to drive cost. And all of this needs to be based on a high level of precision, and an expectation that the overall module is going to be built the same way as the time. So once at the end of that this small lean team have a very specific bill of materials from which the whole business is figured out.

So now you've got a whole lot of content. We still don't know what kind of building we're going to build. Then you bring together and in an engineering world, we call this a Stage Gate process to make it simpler. It's really an all party review. And you have a meeting of that, again, a cross functional team, and you check whether the module design is the right one and if you want to tune The changes, send it back to the drawing board, change the bomb, come up with maybe one or two permutations, not 20, that's the time to make sure you get the green light. And, and, and then once again, you send them all away and create two lean design teams.

So one is going to take these products and design a building, they're going to be looking at the structural aspects of the building, they're going to be looking at the overall architecture, the aspects of the local building codes, the aspects of the site. And now we're actually building a building. And to some extent, that is similar to traditional construction, but it's really formed around the module and the product, and you don't let anybody extend beyond that.

So if you're going to have to four forms of modules, you don't let some of these suddenly design a building into five because it should all be based on the the commodities off the shelf and the details off the shelf. And then in parallel with that a factory is designed if one doesn't exist. And today, what we've seen is people working in spaces that they buy or lease, obviously, there'll be a different story if they had to greenfield, and this is the stage where with the business plan, we discuss output throughput, quality, etc. What are the the finishes? What materials are going in there? Is this a high volume factory? You know, low mix? Or is this going to be a bit of a low, a high mix, low, low volume, maybe it's a high luxury product. And this goes into, you know, the org chart, the quality control the equipment that you're going to use, who you're going to buy things from? Where are you going to get the frame for your module, and then how does that you know, fold into your factory. And, and so now you you've got a building design, and you know how you're going to make the modules. Once again, you stop and get that cross functional team together, see what you've done to the bill of materials, and the cost and the business plan. And make sure that all the work you've done so far, is meeting the goals. And then you can go forward, you can start buying parts and materials. Then you can start getting the factory ready or the site ready, and you can push go.

Now, everything I've just said is a little bit idealistic. Because what's the typical thing in the marketplace is people kind of building the bicycle while they're riding it. And that's not a disaster that can be done. But it does take a degree of discipline to know, you know, the decisions that you're making and make sure that they're very transparent.

John McMullen

Well, that's a fantastic process you just laid out. I'm wondering, though, going back to the developer who's new to modular, the owner who wants to build a modular building, what are some common mistakes that tend to get made by those without experience in modular construction?

Related Reading:

Modular or Offsite Construction is About the Process First, Product Second, Project Third

Developers, often in response to RFQs or their own project needs, start with the project. What kind of building do they want to build? Accustomed to traditional construction, they hire an architect and go down the path of designing the building completely, applying for permits, and preparing to make what was designed.

For offsite and modular construction, this is wrong.

Blair Davies

You know, I wrote some notes or what I was gonna say, but the first one is really, a little bit of a light bulb goes on, I run into some people who have gone off and tried to figure out what they need to do. And then they got kind of married to their decisions. And that's just the sign of not thinking things through and then getting a little too committed and not being objective. And so I think that's a big one.

So first of all, what the next comment would be, I've seen people regularly designing a building, and then trying to turn it into modular, so we get called, they send us drawings. We have to tell them a little bit of a "go, no go" in it. The best thing is to hear more of that what I was describing, which is the space planning how many people are going to live in this place? How much land are we going to be on? What's the layout of typical buildings, the stuff but what typically, what we're seeing developers, the first mistake is they send us a drawing. They've spent all this money designing an actual building, and then they asked to turn it into something modular.

The next thing is, the developer or builder thinks that construction costs will be lower. They're not for the first time, just think very simply, if you have module building, you're going to have two columns side by side, you're going to have two walls, one beside each other. You're going to have a ceiling and a floor, one on top of the other. So right away you're staring at twice the amount of wall and ceilings, floorspace, that kind of thing. And now, with the ability to repeat all that stuff, you're gonna have the ability to bring cost down.

Now the game is speed. So if you start thinking about what is called heads and beds, you should be able to greatly speed up the ability to earn revenue. And that far outweighs the impact on cost. And then the last thing, which is, you know, and this, I think people get this part, which is you now can do things in parallel. So you can be building stuff in factories, while sites are being prepared. I, I think that message has been fairly well communicated, it's still difficult for some people to get their head around. But that's the least worry these days.

John McMullen

What can you tell me about the importance of communication during the project? Are there some best practices that you've learned?

Blair Davies

You know, this also comes from the experience I had, and in other businesses. So strict project management principles, you know, hold meetings, meetings happen on time, action items are recorded, owners of those action items are recorded dates are kept if the date misses, somebody resets their day, simple, straightforward, strict project management. So discipline, keep the team's lean, and make sure they're communicating.

We work with an approach called a RACI document: Responsible, Approval, Consultant, Informed is what to call it, that's what the acronym means. And that means everybody knows who owns what and when. So those, the other things for communication is we have one central database for all information so that people can get to it one source of truth, there's not going to be two designs of people edit or change, you don't download the design, change it and put it back, everybody works with the one place, executives need to have visibility. So they need to be holding 15 minute review meetings regularly, probably more upfront and fewer down the road. But that means any types of major decisions are being made in a very transparent, apparent way.

These Stage Gate reviews that I explained, they're critical to make sure that those lean teams are making good decisions, and that is visible, so that they don't negatively affect the business plan. And lastly, and this is a real gem, you know, know what you do not know, and that's kind of a human comment. But folks get a little married to their decisions, which is what I was saying earlier, and to stay objective and to stand back and go do I really have this figured out and challenge yourselves and have other members of that team challenge to make sure that we know what we don't know, and then go find the people who understand how to how to do this transition.

John McMullen

So you've been a part of a lot of different industries, as you were talking about at the top, you've been, you got back into the building industry and oh, five before that, you're all over the place. I was wondering if you could tell us about some lessons that you've learned, during your time in the building industry or really anywhere? Are there specific projects that you can tell us about that were particularly helpful in your understanding of the potential for modular construction?

Blair Davies

Well claim about it all. So just take away the words and the technologies and all that stuff. Because, in fact, it's a human thing. The idea that a group of human beings should collaborate in a tight and transparent way, is how you get amazing results. And, you know, we used to talk when I was in a pretty sophisticated industry in tech, that you put all these smart people in a room, and they all take their name tags off and throw them in the corner and work for the success of the project. And, and that and also have confidence that the numbers are going to work out. In fact, that's not their problem. Somebody else is going to make sure the companies earn the profits they they deserve.

So in essence, what this industry does by putting the product in the middle and having the various people that contribute to it suppliers, customers, finance, legal distribution, site prep a factory that those folks are collaborating in a discipline project management way to have an outcome. That's and I can describe airplanes, cars, modular buildings. That's, that's what's needed and when I answered the building industry and OPI when I was kind of shocked to see it very linear, very combative. You know, "He who speaks first that is site meeting loses" kind of stuff. Now all of a sudden with modular, it drives this collaboration to such a degree that we can all be successful.

John McMullen

So I know you are a busy guy. What does 2022 look like for you?

Blair Davies

Well, we're seeing more and more developers and builders coming to us to help help them transition to off site construction. And every time we do that, we get better and better. We're not only doing the guidance, consulting and, and rolling up our sleeves and doing but we're also designing and building equipment to go into these factories. And every time we do one, we learned something. And we're seeing that, you know, that invitation for involvement growing quite considerably, probably outpacing the industry.

Because a lot of developers and builders are not necessarily thinking they're going to get their answer from the merchant modular builders that exist today. They want to be in this business. And they can. That's number one. Number two, you are going to see us with products and 22. For both modular builders and steel fabricators, I'll just keep that a little bit in our cards to our chest. But we will be rolling out products that help people as well. So yeah, we're very excited about 2022.

John McMullen

Awesome. So in the meantime, until your products roll out or after, if people wanted to--I know you said you hated the word consult--but if they wanted to consult or pick your brain or get you involved in a project, what's the best way to get in touch with you?

Blair Davies

Our website is catalystoffsite.com. And my email is Blair@catalystoffsite.com. On LinkedIn, all my contact information and phone number and so forth are on on the website. And I look forward to being a strong participant in modular building events. And you'll see me there too.

John McMullen

Well, thank you so much, Blair. This is great, great information. I appreciate your time today. Oh, before you go, I also want to mention that this information is also now available on our website in the format in the form of an article. So thank you, Blair, for putting that together.

Blair Davies

You're very welcome. Thank you.

John McMullen

My name is John McMullen. And this has been another episode of Inside Modular: the Podcast of Commercial Modular Construction. Until next time.